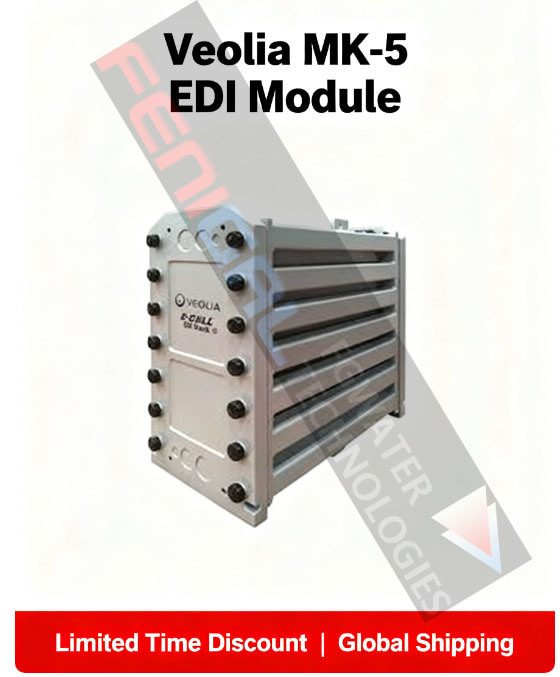

Veolia MK-5 EDI Module (Previously E-CELL-3X) High-Purity Water Solution for Medical Industry

Product Details:

| Place of Origin: | China |

| Brand Name: | VEOLIA |

| Certification: | CE |

| Model Number: | MK-5 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 pc |

|---|---|

| Price: | Negotiable |

| Packaging Details: | standard export packing |

| Payment Terms: | T/T |

| Supply Ability: | 60000 Units per Month |

|

Detail Information |

|||

| MK-5 Minimum Pressure Difference Between Dilute Outlet And Concentrate Inlet (bar):: | 0.34 | MK-5 Dilute Inlet/outlet Standard Pressure Drop (bar):: | 1.4-2.8 |

|---|---|---|---|

| MK-5 Inlet Pressure (bar):: | Counter-current: 4.1-6.9 Co-current: 3.1-6.9 | MK-5 Amperage (ADC):: | 0-5.2 |

| MK-5 Voltage (VDC):: | 0-400 | MK-5 Recovery:: | Up To 97% |

| Designed Water Production (m3 /hr)MK-5:: | 4.0-6.4 | MK-5 Nominal Flow:: | 5.0 M3/h (22 Gpm) |

| MK-5 Application:: | Boiler Feedwater In Power Plants | Highlight:: | Veolia MK-5 EDI Module For Semiconductors, Suez EDI Stacks For Industrial Use, E-CELL-3X Replacement EDI Module |

| Highlight: | Veolia MK-5 EDI module medical industry,EDI module high-purity water solution,Veolia E-CELL-3X replacement EDI module |

||

Product Description

The Veolia MK-5 EDI Module (Previously E-CELL-3X) is a cutting-edge electronic deionization (EDI) system designed to deliver ultra-pure water, critical for precision-dependent sectors like healthcare. As a successor to the trusted E-CELL-3X, this module integrates advanced ion-exchange technology with electric field-driven purification, eliminating the need for chemical regeneration and ensuring consistent, contaminant-free water output.

Core Technology & Process

Leveraging aAgainst the current (counterflow) operation design, the Veolia MK-5 EDI Module efficiently removes ions, organic matter, and microorganisms from feedwater. It combines semipermeable membranes and ion-exchange resins, where an electric field accelerates ion migration—resulting in water purity exceeding 99.9% desalination rate. This chemical-free process reduces environmental impact while maintaining stable performance even in highIncoming water hardness (feedwater hardness) conditions, minimizing cleaning frequency and downtime.

Medical Industry Applications

In healthcare, the module is indispensable for:

• Medical device sterilization: Providing pyrogen-free water for autoclaves and surgical instrument cleaning.

• Pharmaceutical production: Meeting USP/EP standards for drug formulation and API manufacturing.

• Laboratory diagnostics: Ensuring accurate results in clinical tests and molecular biology research.

Specifications Table

|

Parameter |

Value |

|

Rated Flow Rate |

5.0 m³/h (22 gpm) |

|

Flow Range |

2.3 – 6.4 m³/h (10–28 gpm) |

|

Max Operating Pressure |

0.6 MPa |

|

Desalination Rate |

≥99.9% |

|

Certifications |

CE, RoHS compliant |

Competitive Advantages

• Energy Efficiency: Low power consumption and no brine injection reduce operational costs by 30% vs. traditional DI systems.

• Reliability: Counterflow design enhances durability, ideal for 24/7 medical facility operations.

• Regulatory Compliance: Aligns with global healthcare standards, supporting seamless audits.

For medical facilities prioritizing purity, efficiency, and compliance, the Veolia MK-5 EDI Module (Previously E-CELL-3X) sets the benchmark for ultra-pure water solutions.

![]()