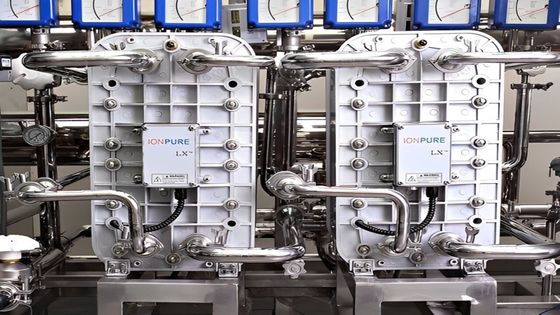

Ionpure LX-Z CEDI Module IP-LXM04Z-5 for Ultrapure Water Systems

Product Details:

| Place of Origin: | China |

| Brand Name: | IONPURE |

| Certification: | CE |

| Model Number: | LXM04Z-5 |

| Document: | fgwater-ionpure-lxz-ds.pdf |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 pc |

|---|---|

| Price: | Negotiable |

| Packaging Details: | standard export packing |

| Delivery Time: | 5- 8 work days |

| Payment Terms: | T/T |

| Supply Ability: | 60000 Units per Month |

|

Detail Information |

|||

| EDI Minimum Flow Rate M3/hr (gpm): | 0.22 (1.0) | EDI Design Flow Rate M3/hr (gpm): | 0.44-0.67 (2.0-3.0) |

|---|---|---|---|

| EDI Shipping Weight Kg (lbs)**: | 59 (130) | EDI Operating Weight Kg (lbs): | 31 (69) |

| EDI Recovery: | 90–95% | EDI Advantages: | Wide Range Of Flow,Low Operating Costs |

| EDI DC Voltage: | 0–400 | DC Amperage: | 1.0–6.0 |

| Highlight: | Ionpure CEDI LX-Z,CEDI LX-Z IP-LXM04Z-5,Ionpure CEDI LX-Z IP-LXM04Z-5 |

||

Product Description

| Attribute | Value |

|---|---|

| EDI Minimum Flow Rate m3/hr (gpm) | 0.22 (1.0) |

| EDI Design Flow Rate m3/hr (gpm) | 0.44-0.67 (2.0-3.0) |

| EDI Shipping Weight kg (lbs) | 59 (130) |

| EDI Operating Weight kg (lbs) | 31 (69) |

| EDI Recovery | 90–95% |

| EDI Advantages | Wide Range Of Flow, Low Operating Costs |

| EDI DC Voltage | 0–400 |

| DC Amperage | 1.0–6.0 |

The IP-LXM04Z-5 is a high-efficiency electrodeionization module designed for continuous, chemical-free production of ultrapure water (up to 18.2 MΩ*cm resistivity). It replaces traditional mixed-bed ion exchange (IX) systems, eliminating chemical regeneration while delivering consistent purity.

- Zero Chemical Operation - Eliminates acids, bases, and regeneration waste; reduces operating costs by >50% vs. conventional IX.

- Mixed-Bed Quality Output - Consistently achieves ≤1 ppb ionic contaminants and ≤10 ppb silica.

- Robust Reliability - Double O-ring seals, resin-filled concentrate chambers, and NSF® 14/61-compliant materials ensure leak-free operation.

- Continuous 24/7 Production - Stable performance without downtime for regeneration; tolerates feedwater fluctuations.

- Certified Manufacturing - CE marked; produced under ISO 9001 (Quality) and ISO 14000 (Environmental) standards.

- Environment: Indoor installation only, away from direct sunlight.

- Temperature: Ambient ≤113°F (45°C) for optimal performance and lifespan.

- Feedwater: Requires reverse osmosis (RO) pretreatment.

- Pharmaceutical water loops (PW, WFI pretreatment)

- Microelectronics rinsing and etching

- Laboratory ultrapure water systems

- Power plant boiler feedwater

- High-purity process water in food/beverage

- Sustainability: No hazardous chemicals or regeneration wastewater.

- Cost Efficiency: Lower OPEX and minimal maintenance.

- Compliance: Meets USP, EP, and JP water quality guidelines for critical applications.

CE marked certified. Each module undergoes rigorous testing before shipment to meet industry high standards, manufactured under ISO 9001 and ISO 14000 quality and environmental management system standards.

Components should be installed indoors, away from direct sunlight, with ambient temperature not exceeding 45°C to ensure stable and efficient operation. This effectively extends component lifespan while ensuring water quality stability and reliability.

| Parameter | Value |

|---|---|

| Recovery | 90-95% |

| DC Voltage | 0-400 |

| DC Current | 1.0-6.0 |

| Product Water Resistivity | Minimum flow >17 MΩ-cm, Maximum flow >7 MΩ-cm |

| Silica (SiO2) Removal | 90-99%, depending on feed conditions |

| Parameter | Requirement |

|---|---|

| Feed Water Conductivity Equivalent | < 40 μS/cm |

| Feed Water Source | RO permeate |

| Temperature | 5-45°C (41-113°F) |

| Inlet Pressure | 1.4-6.9 bar (20-100 psig) |

| Maximum Total Chlorine (as Cl2) | < 0.05 ppm |

| Iron (as Fe) | < 0.01 ppm |

| Manganese (as Mn) | < 0.01 ppm |

| Sulfide (S2-) | < 0.01 ppm |

| pH | 4-11 |

| Total Hardness (as CaCO3) | < 1.0 ppm |

| Dissolved Organics (TOC as C) | < 0.5 ppm |

| Silica (SiO2) | < 1.0 ppm |