MBR Membranes Curtain Modules Based On Enhanced PVDF For Food Processing Wastewater Treatment

Product Details:

| Place of Origin: | China |

| Brand Name: | Fenigal |

| Certification: | CE |

| Model Number: | MBR-N-CO-PVDF |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 pc |

|---|---|

| Price: | Negotiable |

| Packaging Details: | standard export packing |

| Delivery Time: | 5- 8 work days |

| Supply Ability: | 60000 Units per Month |

|

Detail Information |

|||

| Model Name: | MBR-N-CO-PVDF | Core Membrane Material: | CO-PVDF-reinforced PVDF Material With Lining |

|---|---|---|---|

| Product Average Pore Diameter (μm): | 0.05 | Product Highlight: | Internal Aeration, To Ensure Sufficient Vibration Of The Film Filaments, And Strengthen The Air-water Scrubbing Effect |

| The Recommended Operating Cycle Of The Components: | 8 Minutes For Water Production On Every 2 Minutes Stop | Average Pore Diameter (μm): | 0.05 |

| Socket At Both Ends (DN): | 32 | ||

| Highlight: | Food Processing Wastewater Treatment MBR Membranes,Enhanced PVDF MBR Membranes,Curtain Modules MBR Membranes |

||

Product Description

MBR Membranes Curtain Modules Based On Enhanced PVDF For Food Processing Wastewater Treatment

MBR (Membrane Bioreactor) curtain membrane is a wastewater treatment method that combines membrane separation technology and biological treatment technology. Its working principle mainly includes the following aspects:

- Basic structure: MBR curtain membrane system usually consists of a reaction tank and membrane components. The membrane module is composed of a series of thin film sheets, and the surface of the membrane sheet is usually hydrophilic, which can effectively separate liquids and solids.

- Biological reaction process: Wastewater is first sent to a biological reaction tank, where microorganisms (such as bacteria) degrade and transform organic matter in the wastewater to form sludge. This process is carried out under aerobic or anaerobic conditions, depending on the treatment requirements.

- Membrane separation: Wastewater that has undergone biological reactions will flow into the membrane separation unit. The pore size of the membrane is usually between 0.1 and 0.4 microns, which can effectively intercept suspended solids, bacteria, viruses, and other solid particles, while allowing water molecules and some small molecular substances to pass through. The selective filtration characteristic of the membrane significantly improves the effluent quality.

- Operation mode: MBR curtain membrane can be operated by external pressure drive or vacuum suction. The external pressure drive pushes the sewage through the membrane by the pressure of the pump, while the vacuum suction uses the negative pressure under the membrane to extract the water. Both methods have their own advantages and disadvantages, and the specific requirements of the system need to be considered when choosing.

- Sludge reflux: The sludge concentration in MBR systems is usually higher than that in traditional activated sludge processes, which can improve reaction efficiency. Part of the sludge will be returned to the bioreactor to maintain a high microbial concentration and further improve the treatment efficiency.

- Water treatment: The water quality after membrane separation is very clear and can meet the standards for reuse. The effluent can be used for non potable purposes such as irrigation and toilet flushing, and even for drinking water after further treatment.

- Advantages: MBR curtain membrane system has many advantages compared to traditional sewage treatment technology, including small footprint, stable operation, good effluent quality, low sludge production, and is suitable for industrial and urban sewage treatment.

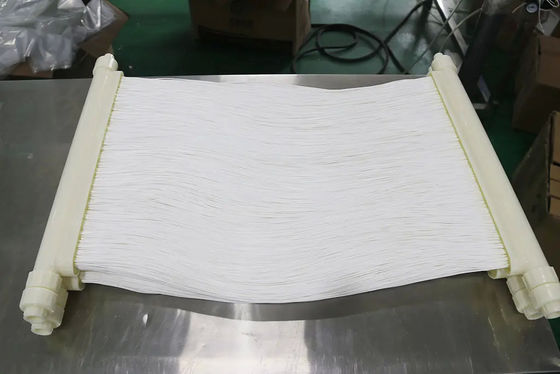

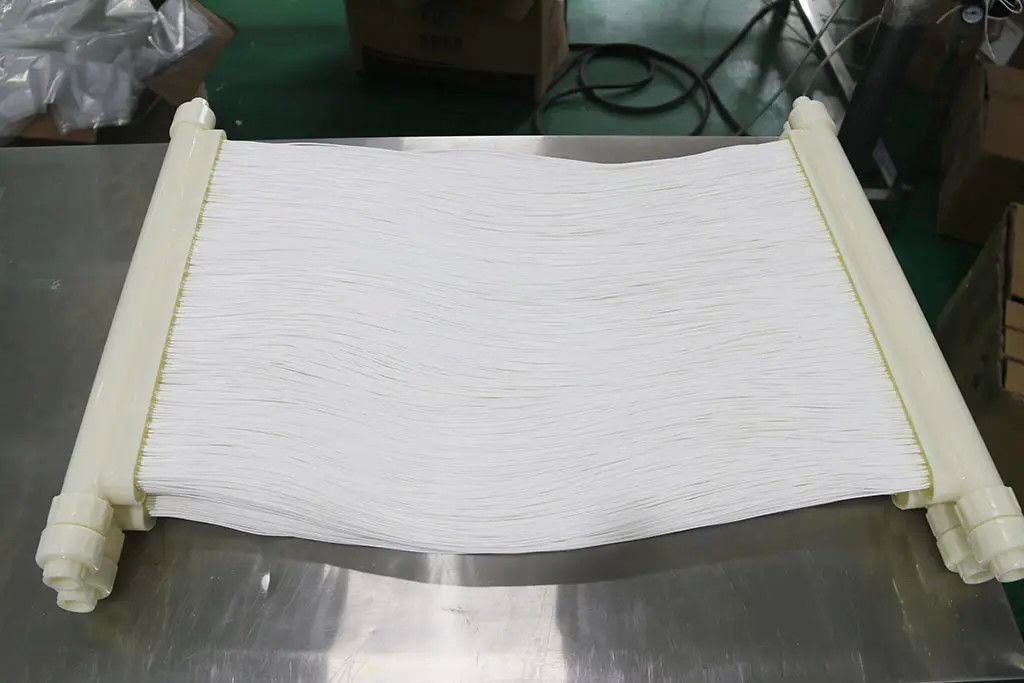

MBR membrane (reinforced PVDF membrane)

![]()

Highlight: Internal aeration, to ensure sufficient vibration of the film filaments, and strengthen the air-water scrubbing effect

Model of reinforced polyvinylidene fluoride hollow fiber curtain membrane module (MBR membrane)

Model name: MBR-N-CO-PVDF

MBR——MBR membrane

N——membrane area number

CO-PVDF-reinforced PVDF material with lining

Example: MBR-10-CO-PVDF: 10 square meters with an MBR membrane lined with PVDF material

Performance parameters of lined reinforced polyvinylidene fluoride hollow fiber curtain membrane module (MBR membrane)

| Membrane module model | MBR-8-CO-PVDF | MBR-10-CO-PVDF | MBR-15-CO- PVDF | |

| Component parameters | Membrane material and technology | PVDF material (reinforced with woven fiber lining)—NIPS process | ||

| Effective membrane area (㎡) | 8 | 10 | 15 | |

| Average pore diameter (μm) | 0.05 | |||

| Component patented design | membrane aeration-enhanced anti-pollution design | |||

| Module size | Total length × total width (mm) | 1050×645 | 1550×645 | 1550×645 |

| Number of membrane filaments | 1600 | 1200 | 1800 | |

| Interface size | Socket at both ends (DN) | 32 | ||

| Component connection | PE hose (mm) | 14 | ||

| Conditions of use | Filtration method | Negative pressure suction filtration | ||

| Maximum trans-membrane pressure difference (MPa) | -0.08 | |||

| Applicable temperature range (℃) | 5~45 | |||

| Long-term tolerant pH range | 2~13 | |||

| Average aeration volume of components (Nm³/h) | 3-5 | 4-6 | 6-9 | |

| Recommended sludge concentration (MLSS) | 6000~10000 | |||

| 25℃ design flux | 14~22 | |||

| The recommended operating cycle of the components | 8 minutes for water production on every 2 minutes stop | |||

|

1. All technical parameters in the table are factory inspection values under standard inspection conditions. 2. The production water flow in the table refers to the actual production water design flow when the product is used for MBR technology to treat sewage. |

||||

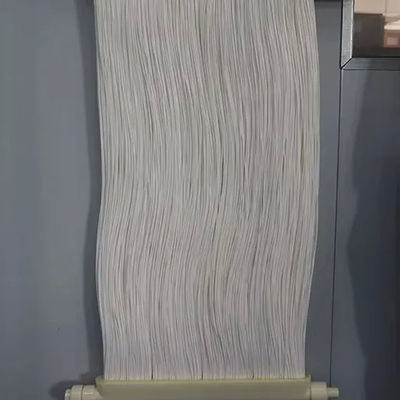

![]()

High-strength lining MBR membrane module (MBR membrane) is currently the core filtration membrane module that is more suitable for MBR membrane bioreaction systems. The reinforced polyvinylidene fluoride (PVDF) hollow fiber curtain membrane module (with MBR membrane lining) has advanced structure and superior performance (patent name: anti-blocking and high aeration efficiency hollow limit curtain membrane module, utility model Patent number: ZL 2017 2015 7728.4), mainly composed of reinforced polyvinylidene fluoride hollow fiber membrane, air inlet pipe, internal aeration pipe and water outlet pipe. Unique internal aeration structure (patented technology)

The reinforced PVDF curtain membrane with lining is composed of air inlet pipe, outlet pipe, internal aeration pipe and reinforced type with lining

Composed of PVDF hollow fiber membranes, the structure of the built-in aeration tube greatly improves the air scrubbing effect of the curtain membrane during use, which is beneficial to the stability of membrane operation.

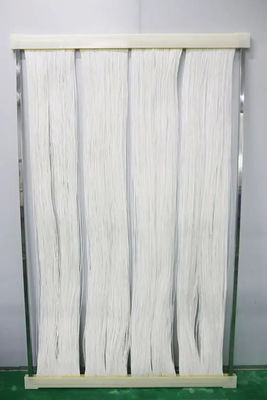

【Membrane module + SS304 Install Frame】

![]()

【Application field】

1. Upgrading of sewage treatment facilities and centralized treatment stations for rural sewage.

2. General wastewater: domestic wastewater, effluent from municipal sewage station.

3. High-concentration organic wastewater: food processing wastewater, breeding wastewater, slaughterhouse wastewater, etc.

4. Refractory industrial wastewater: printing and dyeing, chemical, pharmaceutical, coking wastewater, landfill leachate, etc.

![]()

About Us

FG Water Technologies (www.fgwater.com) is now an organic part of Wuxi Fenigal Science and Technology Co. Ltd., which is a high-tech entity integrating water treatment quipment design, manufacturing, trading and shipment served for main industrial sectors.

HAFE-FG Water Technologies has focused on the research of water treatment technology, equipment development and manufacturing, testing and international shipment etc. We work with many leading large-scale or small-medium original equipment manufacturers in China High-tech Development Zones, and engaged ourselves in R&D, manufacturing, and quality testing.

Our main products include a variety of water purification and different treatment equipment, such as seawater reverse osmosis (SWRO) system, brackish water rever osmosis (BWRO), ultrafiltration (UF)system, Electrodeionization/EDI equipment, media pressure filters and ion exchanger softeners. So far, our company has become a major water treatment equipment supplier for food and beverage industry, pharmaceutical industry, chemical industry, electric power industry, urban water supply industry, municipal and industrial wastewater treatment and more industries, as well as being an exporter to more than 20 countries and regions in Asia, Europe, the Americas, Africa, etc.

OUR CLIENTS

![]()

INDUSTRIES SERVED

![]()

PRODUCTION SYSTEM

Our production system consist of a list of industry-specialized partnership factories accross China. Some of them singularly cover an area of over 10,000 square meters, including 5,000 square meters of workshop and warehouse and 1,500 square meters of office buildings. All of our technical staff has more than 10 years of experience in the design of water treatment systems, so we are able to provide the perfect solution for all kinds of water purification and sewage treatment applications.

Since the establishment, the Company has always regarded quality as the life of our business. We choose the best components only for the production of various water treatment systems. Our systems are easy to use and maintain, and they stays highly reliable even under toughest conditions.

Our FACTORY

![]()