Chinese brands EDI Modules that can help you optimize costs KXA Series KXA-200 1.5-2.5 M3/H

Product Details:

| Place of Origin: | China |

| Brand Name: | China brand |

| Certification: | CE |

| Model Number: | KXA-200 |

| Document: | KXA Series Parameter Table.pdf |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 pc |

|---|---|

| Price: | Negotiable |

| Packaging Details: | standard export packing |

| Delivery Time: | 5- 8 work days |

| Supply Ability: | 60000 Units per Month |

|

Detail Information |

|||

| Stack Water Production Flow(m³/h): | 1.5-2.5 | Stack Standard Water Production Flow(m³/h): | 2 |

|---|---|---|---|

| Product Resistivity Of Produced Water (MO·cm): | 15-18.25 | Product Stack Silicon And Boron Removal Rate (%): | ≥99 |

| Product Advantages: | Optimize Costs | Application: | Pharmaceutical & Biotechnology |

| Origin: | China | ||

Product Description

Chinese brands EDI Modules that can help you optimize costs KXA Series KXA-200 1.5-2.5 M3/H

KXA EDI Electrodeionization Membrane Stack

Innovative Water Purification Technology from China

1. Core Technology & Working Principle

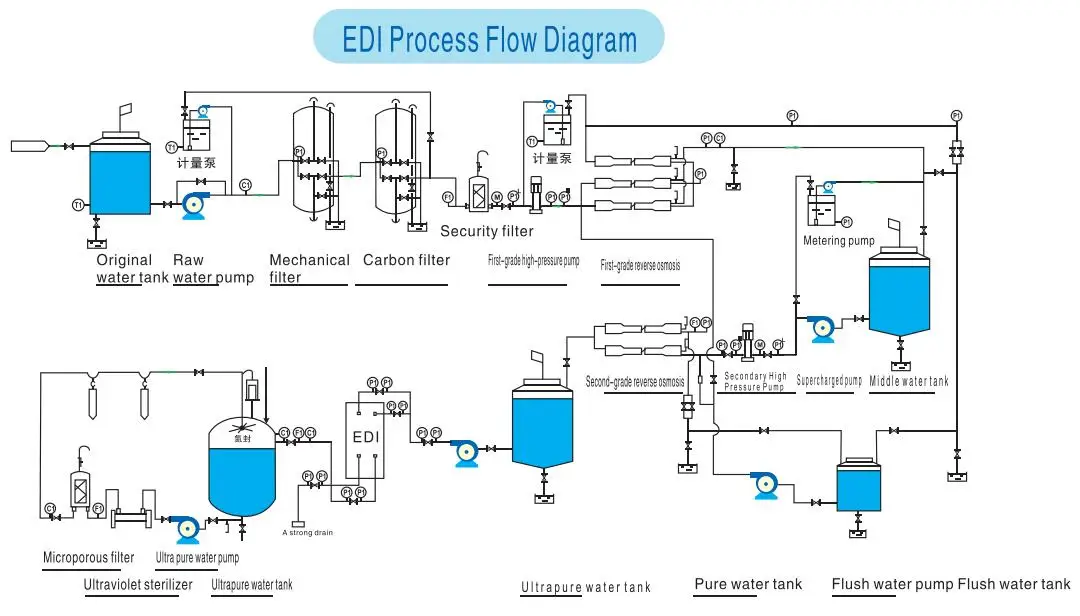

The KXA EDI membrane stack integrates electrodialysis (ED) and ion exchange (IX) technologies to achieve continuous deionization without chemical regeneration. Its structure consists of:

- Alternating cation/anion exchange membranes and mixed-bed ion exchange resins (sulfonic acid-type cation resin + quaternary amine-type anion resin) packed in diluted (product water) chambers .

- Under a DC electric field, ions in feed water migrate directionally:

- Cations move toward the cathode through cation-exchange membranes.

- Anions move toward the anode through anion-exchange membranes.

- Ions are trapped in concentrated chambers, while H⁺/OH⁻ ions generated by water splitting automatically regenerate the resins, enabling zero-chemical operation .

2. Key Advantages

- Zero Chemical Regeneration: Eliminates acid/alkali consumption and hazardous waste disposal, reducing operational costs and environmental impact .

- Continuous High-Purity Output: Produces ultrapure water with resistivity up to 18.2 MΩ·cm (exceeding ISO Class 3 standards) .

- High Recovery Rate: Achieves >90% water utilization by recycling concentrated and electrode streams to the RO inlet .

- Compact & Automated Design: Modular structure allows flexible scaling; fully automated operation requires minimal supervision .

- Using the full filling technology of the middle partition, the water quality is good

- No need to add salt and concentrate water circulation, easy to operate

- Excellent electrical performance, high current efficiency, low voltage, low energy consumption

- Pipelines are arranged side by side, two inlet and two outlet standard threaded interfaces, easy to install

- Perfect structural design to ensure zero leakage

- purified water

- feed to WFI (Water For Injection) stills

- stream generation / boiler feed during power generation

- microelectronics/semiconductor production

- for high quality makeup demineralized water

- for biomedical and laboratory use, by pharmaceutical compounds as pretreatment for distillation

- surface finishing

- chemical manufacturing

- food and beverage industry

-Boiler feedwater for power, chemical and metallurgical industries

-Super pure water for electronics, semiconductors and precision machinery

-Water for chemical processes

-Medical water

-Ultrapure lab water

| Water output |

KXA-50 |

KXA-100 | KXA-200 | KXA-300 | KXA-400 | KXA-500 | KXA-600 | KXA-700 |

| Water flow range(m³/h) | 0.3-0.7 | 0.5-1.4 | 1.5-2.5 | 2.5-3.5 | 3-4.5 | 4.5-5 | 5-6.5 | 5.5-7.5 |

| Standard water flow rate(m³/h) | 0.5 | 1.0 | 2.0 | 3.0 | 4.0 | 5.0 | 6.0 | 7.0 |

| Resistivity of produced water (MO·cm) | 15-18.25 | 15-18.25 | 15-18.25 | 15-18.25 | 15-18.25 | 15-18.25 | 15-18.25 | 15-18.25 |

| Silicon and boron removal rate (%) | ≥99 | ≥99 | ≥99 | ≥99 | ≥99 | ≥99 | ≥99 | ≥99 |

| Recovery rate% | 90-95 | 90-95 | 90-95 | 90-95 | 90-95 | 90-95 | 90-95 | 90-95 |

For application cases, please click:https://www.fgwater.com/Industries/

![]()

About Us

FG Water Technologies (www.fgwater.com) is now an organic part of Wuxi Fenigal Science and Technology Co. Ltd., which is a high-tech entity integrating water treatment quipment design, manufacturing, trading and shipment served for main industrial sectors.

HAFE-FG Water Technologies has focused on the research of water treatment technology, equipment development and manufacturing, testing and international shipment etc. We work with many leading large-scale or small-medium original equipment manufacturers in China High-tech Development Zones, and engaged ourselves in R&D, manufacturing, and quality testing.

Our main products include a variety of water purification and different treatment equipment, such as seawater reverse osmosis (SWRO) system, brackish water rever osmosis (BWRO), ultrafiltration (UF)system, Electrodeionization/EDI equipment, media pressure filters and ion exchanger softeners. So far, our company has become a major water treatment equipment supplier for food and beverage industry, pharmaceutical industry, chemical industry, electric power industry, urban water supply industry, municipal and industrial wastewater treatment and more industries, as well as being an exporter to more than 20 countries and regions in Asia, Europe, the Americas, Africa, etc.

OUR CLIENTS

![]()

PRODUCTION SYSTEM

Our production system consist of a list of industry-specialized partnership factories accross China. Some of them singularly cover an area of over 10,000 square meters, including 5,000 square meters of workshop and warehouse and 1,500 square meters of office buildings. All of our technical staff has more than 10 years of experience in the design of water treatment systems, so we are able to provide the perfect solution for all kinds of water purification and sewage treatment applications.

Since the establishment, the Company has always regarded quality as the life of our business. We choose the best components only for the production of various water treatment systems. Our systems are easy to use and maintain, and they stays highly reliable even under toughest conditions.