EDI Modules KXA Series KXA-400 3-4.5 M3/H For Laboratories

Product Details:

| Place of Origin: | China |

| Brand Name: | China brand |

| Certification: | CE |

| Model Number: | KXA-400 |

| Document: | KXA Series Parameter Table.pdf |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 pc |

|---|---|

| Price: | Negotiable |

| Packaging Details: | standard export packing |

| Delivery Time: | 5- 8 work days |

| Supply Ability: | 60000 Units per Month |

|

Detail Information |

|||

| EDI Module Water Production Flow(m³/h): | 3-4.5 | EDI Module Standard Water Production Flow(m³/h): | 4 |

|---|---|---|---|

| EDI Module Resistivity Of Produced Water (MO·cm): | 15-18.25 | Module Stack Silicon And Boron Removal Rate (%): | ≥99 |

| Module Advantages: | Optimize Costs | Application: | Laboratories |

| Origin: | China | ||

| Highlight: | Laboratories EDI Modules,KXA Series EDI Modules,3-4.5 M3/H EDI Modules |

||

Product Description

EDI Modules KXA Series KXA-400 3-4.5 M3/H For Pharmaceuticals

The EDI Revolution: Water Purification Without Compromise

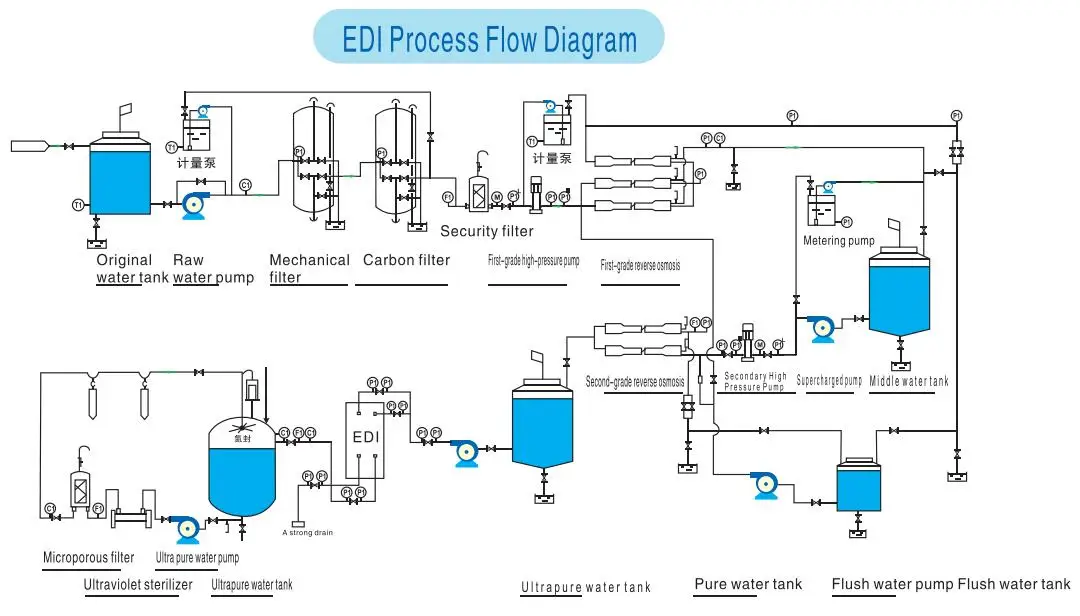

Electrodeionization (EDI) membrane stacks redefine ultra-pure water production by merging electrochemical separation and self-sustaining regeneration into one seamless process. Imagine eliminating tons of corrosive chemicals while achieving water purity levels once thought impossible — this is the promise of EDI.

How It Redefines Purification:

At its heart, an EDI stack operates like a "molecular sieve with a battery." Alternating cation-exchange and anion-exchange membranes create purified channels (dilute streams) and contaminant traps (concentrate streams). But the true genius lies in its self-healing core: Mixed-bed ion exchange resins between the membranes not only capture ions but also leverage water electrolysis (H₂O → H⁺ + OH⁻) under a low-voltage DC field. These regenerating ions constantly refresh the resin beds — no acid tanks, no alkali drums, no shutdowns. Contaminants are flushed away in real time, achieving 18.2 MΩ·cm resistivity continuously.

Why Industries Are Shifting to EDI:

- Legacy Systems Obsoleted: Traditional ion exchange demands hazardous chemicals, storage tanks, regeneration downtime, and waste treatment. EDI replaces this with a compact, skid-mounted module running silently 24/7.

- Precision at Scale: Semiconductor fabs need sub-ppb metal removal; biotech labs require endotoxin-free water. EDI delivers consistent purity at flows from 100 to 5,000+ L/h — scaling linearly by stacking modules.

- Resource Efficiency: >90% water recovery via closed-loop concentrate recycling slashes wastewater costs. Energy use plummets 60% versus conventional electrodialysis due to conductive resin matrix technology.

The Critical Edge in Industrial Applications:

In Silicon Valley cleanrooms, EDI’s ppb-level sodium rejection safeguards nanoscale circuitry. For vaccine producers, its chemical-free operation guarantees USP Chapter <1231> compliance. Power plants deploy it to banish boiler scaling with <0.1 µS/cm water. Even green hydrogen pioneers trust EDI to scrub electrolyzer feedwater to <10 ppb silica — a non-negotiable for catalyst longevity.

Engineering Breakthroughs Enabling This:

- Patented Monobloc Resin Matrix™: Fully resin-filled chambers maximize ion transfer efficiency, resisting flow channeling.

- Corrosion-Proof Electrodes: Platinum-coated titanium sustains performance in oxidizing environments.

- Shock-Resistant Membranes: Reinforced with PET webbing to handle pressure spikes up to 7 bar.

Sustainability Quantified:

One pharmaceutical plant cut 12,000 liters/year of hydrochloric acid disposal after switching to EDI. A semiconductor fab reduced water waste by 2.8 million gallons annually. This aligns with UN SDG 6 (Clean Water) while slashing operational costs 50–70%.

- Using the full filling technology of the middle partition, the water quality is good

- No need to add salt and concentrate water circulation, easy to operate

- Excellent electrical performance, high current efficiency, low voltage, low energy consumption

- Pipelines are arranged side by side, two inlet and two outlet standard threaded interfaces, easy to install

- Perfect structural design to ensure zero leakage

- purified water

- feed to WFI (Water For Injection) stills

- stream generation / boiler feed during power generation

- microelectronics/semiconductor production

- for high quality makeup demineralized water

- for biomedical and laboratory use, by pharmaceutical compounds as pretreatment for distillation

- surface finishing

- chemical manufacturing

- food and beverage industry

-Boiler feedwater for power, chemical and metallurgical industries

-Super pure water for electronics, semiconductors and precision machinery

-Water for chemical processes

-Medical water

-Ultrapure lab water

| Water output |

KXA-50 |

KXA-100 | KXA-200 | KXA-300 | KXA-400 | KXA-500 | KXA-600 | KXA-700 |

| Water flow range(m³/h) | 0.3-0.7 | 0.5-1.4 | 1.5-2.5 | 2.5-3.5 | 3-4.5 | 4.5-5 | 5-6.5 | 5.5-7.5 |

| Standard water flow rate(m³/h) | 0.5 | 1.0 | 2.0 | 3.0 | 4.0 | 5.0 | 6.0 | 7.0 |

| Resistivity of produced water (MO·cm) | 15-18.25 | 15-18.25 | 15-18.25 | 15-18.25 | 15-18.25 | 15-18.25 | 15-18.25 | 15-18.25 |

| Silicon and boron removal rate (%) | ≥99 | ≥99 | ≥99 | ≥99 | ≥99 | ≥99 | ≥99 | ≥99 |

| Recovery rate% | 90-95 | 90-95 | 90-95 | 90-95 | 90-95 | 90-95 | 90-95 | 90-95 |

For application cases, please click:https://www.fgwater.com/Industries/

![]()

About Us

FG Water Technologies (www.fgwater.com) is now an organic part of Wuxi Fenigal Science and Technology Co. Ltd., which is a high-tech entity integrating water treatment quipment design, manufacturing, trading and shipment served for main industrial sectors.

HAFE-FG Water Technologies has focused on the research of water treatment technology, equipment development and manufacturing, testing and international shipment etc. We work with many leading large-scale or small-medium original equipment manufacturers in China High-tech Development Zones, and engaged ourselves in R&D, manufacturing, and quality testing.

Our main products include a variety of water purification and different treatment equipment, such as seawater reverse osmosis (SWRO) system, brackish water rever osmosis (BWRO), ultrafiltration (UF)system, Electrodeionization/EDI equipment, media pressure filters and ion exchanger softeners. So far, our company has become a major water treatment equipment supplier for food and beverage industry, pharmaceutical industry, chemical industry, electric power industry, urban water supply industry, municipal and industrial wastewater treatment and more industries, as well as being an exporter to more than 20 countries and regions in Asia, Europe, the Americas, Africa, etc.

OUR CLIENTS

![]()

PRODUCTION SYSTEM

Our production system consist of a list of industry-specialized partnership factories accross China. Some of them singularly cover an area of over 10,000 square meters, including 5,000 square meters of workshop and warehouse and 1,500 square meters of office buildings. All of our technical staff has more than 10 years of experience in the design of water treatment systems, so we are able to provide the perfect solution for all kinds of water purification and sewage treatment applications.

Since the establishment, the Company has always regarded quality as the life of our business. We choose the best components only for the production of various water treatment systems. Our systems are easy to use and maintain, and they stays highly reliable even under toughest conditions.