and better economic than general ion exchange method and distillation method.

Fouling Resistant RO Membrane Elements Vontron FR Series For Pure Water Production

Product Details:

| Place of Origin: | China |

| Brand Name: | Vontron |

| Certification: | CE |

| Model Number: | FR Series |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 pc |

|---|---|

| Price: | Negotiable |

| Packaging Details: | standard export packing |

| Delivery Time: | 5- 8 work days |

| Supply Ability: | 60000 Units per Month |

|

Detail Information |

|||

| Element Stable Rejection Rate(%): | 99.5 | Element Permeate Flow GPD(m3/d): | 2200(8.3) |

|---|---|---|---|

| Element Active Membrane Area Ft2(m2): | 90(8.4) | Element Feed Spacer Thickness Mil: | 34 |

| Element Maximum Operating Pressure Psi(MPa): | 600(4.14) | Element Maximum Feedwater Temperature °C: | 45 |

| Element Maximum Inlet Flow Rate M3/h: | 3.6 | Element Maximum Concentration Of Free Chlorine Mg/L: | 0.1 |

| Element Application: | Pure Water Production | ||

| Highlight: | Pure Water Production RO Membrane Elements,Vontron FR Series RO Membrane Elements,Fouling Resistant RO Membrane Elements |

||

Product Description

Fouling Resistant RO Membrane Elements - Vontron FR Series For Pure Water Production

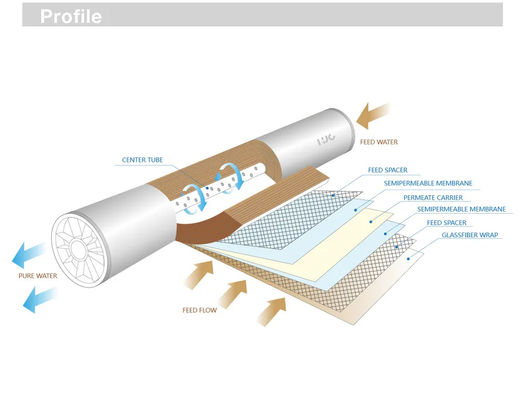

FR Series RO Membrane Element utilizes specialized manufacture technique that can improve the hydrophilicity, electric charge and roughness of its surface, thus reducing the breeding and adsorption of pollutants and microbes on membrane surface.

◎ Pure water production from surface water, for example: lake water, river water, etc.

◎ Desalination of Reclaimed water, for example: Reclaimed water, industrial wastewater, RO concentrated water, etc.

and better economic than general ion exchange method and distillation method.

More models

![]()

2. Max Working Pressure: 600psi(4.14Mpa)

3. Average Permeate: 9600GPD

The service life of the membrane is not specific to determine the answer, the general service life is 1-2 years. It depends on the quality of raw water, the size of water consumption, the proportion of pure water and wastewater equipment, prefilter material and equipment operating pressure, which will affect the service life of RO membrane.

Q: What is the difference between model 21 and model 31?

The capacity of model 21 is slightly larger, but the TDS is slightly higher. The capacity of the model 31 is not as large as that of the model 21, but the water quality is better.

Q:What is the difference between ULP and LP?

ULP is low-pressure reverse osmosis membrane, the working pressure is 6-8 kg;

LP is high-pressure reverse osmosis membrane, the working pressure is 15kg;

when choosing, please know the required product model in detail.

Q: What is your terms of payment ?

A: Payment<=1000USD, 100% in advance. Payment>=1000USD, 30% T/T in advance ,balance before shippment.

About Us

FG Water Technologies (www.fgwater.com) is now an organic part of Wuxi Fenigal Science and Technology Co. Ltd., which is a high-tech entity integrating water treatment quipment design, manufacturing, trading and shipment served for main industrial sectors.

HAFE-FG Water Technologies has focused on the research of water treatment technology, equipment development and manufacturing, testing and international shipment etc. We work with many leading large-scale or small-medium original equipment manufacturers in China High-tech Development Zones, and engaged ourselves in R&D, manufacturing, and quality testing.

Our main products include a variety of water purification and different treatment equipment, such as seawater reverse osmosis (SWRO) system, brackish water rever osmosis (BWRO), ultrafiltration (UF)system, Electrodeionization/EDI equipment, media pressure filters and ion exchanger softeners. So far, our company has become a major water treatment equipment supplier for food and beverage industry, pharmaceutical industry, chemical industry, electric power industry, urban water supply industry, municipal and industrial wastewater treatment and more industries, as well as being an exporter to more than 20 countries and regions in Asia, Europe, the Americas, Africa, etc.

OUR CLIENTS

![]()

INDUSTRIES SERVED

![]()

PRODUCTION SYSTEM

Our production system consist of a list of industry-specialized partnership factories accross China. Some of them singularly cover an area of over 10,000 square meters, including 5,000 square meters of workshop and warehouse and 1,500 square meters of office buildings. All of our technical staff has more than 10 years of experience in the design of water treatment systems, so we are able to provide the perfect solution for all kinds of water purification and sewage treatment applications.

Since the establishment, the Company has always regarded quality as the life of our business. We choose the best components only for the production of various water treatment systems. Our systems are easy to use and maintain, and they stays highly reliable even under toughest conditions.

Our FACTORY

![]()