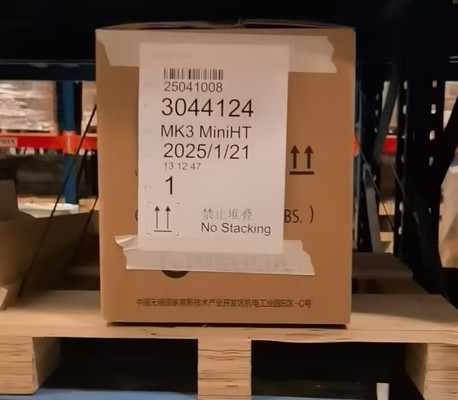

Veolia E-Cell MK-3 Mini HT EDI module for pharmaceutical ultrapure water production

Product Details:

| Place of Origin: | China |

| Brand Name: | VEOLIA |

| Certification: | CE |

| Model Number: | Veolia EDI MK-3MiniHT |

| Document: | FSpwE-CellMK-3MiniHT_EN.pdf |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 pc |

|---|---|

| Price: | Negotiable |

| Packaging Details: | standard export packing |

| Delivery Time: | 1 month |

| Payment Terms: | T/T |

| Supply Ability: | 60000 Units per Month |

|

Detail Information |

|||

| MiniHT Flow Rate Range: | 0.5–1.6 M3 /h (2.2–7.0 Gpm) | MiniHT Product Shipping Weight: | 57 Kg (126 Lbs) |

|---|---|---|---|

| MiniHT Dimensions Of This Model (width X Height X Depth): | 30 Cm X 61 Cm X 29 Cm | MiniHT Resistivity: | ≥ 10 (Pharmaceutical) Or ≥ 16 MOhm-cm (Industrial |

| Product Sodium: | ≤ 3 Ppb (industrial) | Product Maximum Sanitization Temperature: | 85ºC (185ºF) |

| Product Maximum Sanitization Inlet Pressure: | 2.1 Bar (30 Psi) | Product Application: | Pharmaceutical And Laboratory Purified Water Compliant With USP And EP |

| Highlight: | Veolia E-Cell MK-3 EDI module,pharmaceutical ultrapure water EDI,mini HT EDI module |

||

Product Description

The Veolia E-Cell MK-3 Mini HT Electrodeionization (EDI) Module is designed for polishing reverse osmosis (RO) permeate to produce ultra-pure water. It delivers high-purity water (up to 10 MΩ·cm resistivity, with ≤5 ppb silica) without chemical regeneration. Ideal for power generation, semiconductors, microelectronics, and pharmaceuticals, this compact module (30x61x28 cm) offers continuous operation, high recovery rates (78-93%), and hot water sanitization capabilities

| Flow Rate Range | 0.5–1.6 m³/h (2.2–7.0 gpm) |

| Shipping Weight | 57 kg (126 lbs) |

| Dimensions | 30 cm x 61 cm x 29 cm |

| Resistivity | ≥ 10 MOhm-cm (Pharmaceutical) or ≥ 16 MOhm-cm (Industrial) |

| Maximum Sanitization Temperature | 85ºC (185ºF) |

- Patented HT-EDI™ technology for reagent-grade water production

- 90% lower energy consumption compared to mixed-bed systems

- Maintenance-free operation with intelligent control system

- Real-time monitoring of conductivity, pH, and pressure drop

- Patented staggered flow channel design prevents scaling

Maintains resistivity above 18.2 MΩ*cm with 22% energy reduction compared to traditional EDI equipment. Achieves recovery rates exceeding 90% even with high-hardness raw water.

- Basic Unit - Standalone purification

- RO-EDI Integrated - Complete purification skid

- GMP Version - With full validation support

- CE, RoHS, CSA and EAC marked

- FDA-compliant materials

- UKCA certified

- Manufactured in ISO 9001 and ISO 14001 facility

- Halal certified by IFANCA®

| Parameter | Value |

|---|---|

| Inlet Pressure | 6.9 bar (100 psi) |

| Max Temperature | 40°C (104°F) |

| Pressure Drop | 1.4-2.8 bar (20-40 psi) |

| Recovery Rate | Up to 93% |

| Conductivity | <117 µS/cm |

| pH Range | 4-11 |

Ideal for water for injection, pharmaceutical purified water, and laboratory purified water systems. Complies with USP, EP, and other pharmacopeia standards.

FG Water Technologies is a high-tech entity specializing in water treatment equipment design, manufacturing, and international shipment. Our products serve various industries including pharmaceutical, food and beverage, chemical, and power.