6000L/H Ion Exchange Water Purification System Dual Tank

Product Details:

| Place of Origin: | China |

| Brand Name: | Fenigal/OEM |

| Certification: | CE/NSF etc. |

| Model Number: | WS-X |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 Set |

|---|---|

| Price: | Negotiable |

| Packaging Details: | Standard Export Wood Crate/Carton or Naked wrapped by film/Containerized |

| Delivery Time: | 15~30 days |

| Payment Terms: | T/T, Western Union, Paypal etc. |

| Supply Ability: | 200 set per month |

|

Detail Information |

|||

| Technology: | Ion Exchange | Material: | FRP |

|---|---|---|---|

| Design: | Skid Mount/containerized | Water Temp.: | 5~35˚C |

| Water Flow Rate: | Up To 1,000 M3/day.vessel | Voltage: | 380V,415V,220V,can Be Customized |

| Application: | Surface, Underground Water, Sewage Water Treatment | Size: | Dia.50cm~200cm |

| Highlight: | 6000L/H Ion Exchange Water Purification System,200cm Ion Exchange Water Purification System,6000L/H dual tank water softener systems |

||

Product Description

Dual tank alternating water softener to remove dissolved minerals (hardness salts) 6000L/hr

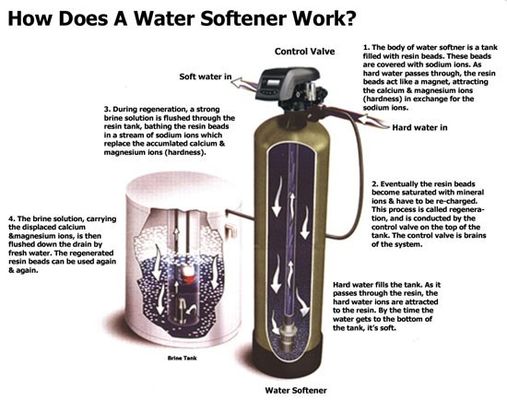

What is a Water Softener? The water softener is just a special type of "filter" that removes the calcium and magnesium in hard water by using plastic beads and cleans itself periodically by a process called “regeneration.”

Water softeners have three main components: A mineral tank, brine tank and control valve. Smaller capacity models combine the mineral tank and brine tanks into one cabinet, but the two tanks are still separated within the cabinet.

Larger flow capacity systems have separate stand alone mineral and brine tanks.

Ion exchange is a well known type of water softening system that has been available for quite a long time. Ion exchange replaces the calcium and magnesium in water with salt, potassium or hydrogen. Of these three options salt is perhaps the best known water softening regeneration solution.

An ion exchange water softener consists of a resin tank and a brine tank. The water passes through the resin bed and the hardness mineral ions in the water are exchanged for sodium (or potassium) ions. When the resin is saturated with hardness minerals the systems goes through a regeneration cycle that flushes brine solution through the resin bed exchanging the hardness mineral ions with sodium ions. The hardness minerals are then washed down the drain leaving the resin ready to go through the process again.

After the water softener treats the water the water enters the household water supply as soft water. Softened water will contain either sodium or potassium depending on which is used in the softening process.

Sodium more readily available and less expensive than potassium but there are concerns about the additional sodium intake particularly for anyone on a low sodium diet. Other concerns with regards to the use of sodium is the environmental effects of the large amounts of salt that are released into the waste water supply during the regeneration cycle.

Technoloty index and working

01.Water pressure:0.18-0.6Mpa

02.Working temperature:1°c-55°c

03.Hardness of raw water: <8mmol/L

04.Operation method:manual/automatic

05.Hardness of effluent water: ≤0.03mmol/L

06.water flow: 0.3-20 t/h

Rebirth method:resin exchange with ion inw water

Control method: time or flow

Working electric: 220V/50Hz

Usage:

System automatic water softener widely used in steam boiler, heating boiler, exchanger, air conditioner, and other systems water softener, also used in hotel, restaurant, office, and other life water treatment and food, drinking, wine, washing, textile, chemical, medicine and other industrial softener water treatment.

![]()

| Parameter | Units | MF-M50 | MF- M150 | MF-M250 | MF-M500 | MF-L1000 | MF-L2500 | MF-L5000 | |

| Filtrate flow rate*1 | m3/day | 50 | 150 | 250 | 500 | 1,000 | 2,500 | 5,000 | |

| Feed/filtrate water flow | m3/hr | 2.1 | 6.4 | 10.6 | 21.3 | 42.6 | 106.4 | 212.8 | |

| Backwash water flow | m3/hr | 1.5~3 x feed water flow | |||||||

| Power consumption | Feed/backwash pump*2, *3 | kW | 1.1 | 2.2 | 3 | 5.5 | 11 | 30 | 55 |

| Air conditioned containers*2 | 1.9 kW per 20’ container / 3.8 kW per 40’ container | ||||||||

| Power supply | - | AC 415V, 3 Phase 50 Hz | |||||||

| Recovery rate | % | 90~98% | |||||||

| Filtration velocity | Sand Media | m/hr | 20 (design value can be adjusted ) | ||||||

| DMI-65 media | 10 (design value can be adjusted ) | ||||||||

| Empty bed contact time | GAC media | min. | 10 (design value can be adjusted ) | ||||||

| UV dose rate*2 | mJ/cm2 | Typical >40 @ 90% UVT | |||||||

| Feed/backwash water inlet | Without pump | kPa | 300~600 (pressurised feed/backwash water by client) | ||||||

| pressure | With pump | ≥20 (flooded suction) | |||||||

| Pressure drop | Sand media | kPa | 50~200 | ||||||

| DMI-65 media | 50~200 | ||||||||

| GAC media | 50~200 | ||||||||

| Cartridge filter*2 | 50~200 | ||||||||

| Ambient | Skid mounted | °C | 5~30 | ||||||

| temperature | Containerised | -5~40 | |||||||

| (min/max) | Containerised with insulation | -15~50 | |||||||

![]()