90m3/H Reverse Osmosis System Water Waste Purification

Product Details:

| Place of Origin: | China |

| Brand Name: | Fenigal/OEM |

| Certification: | CE/NSF etc. |

| Model Number: | WTS-18 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 Set |

|---|---|

| Price: | Negotiable |

| Packaging Details: | Standard Export Wood Crate/Carton or Naked wrapped by film |

| Delivery Time: | 15~30 days |

| Payment Terms: | T/T, Western Union, Paypal etc. |

| Supply Ability: | 200 set per month |

|

Detail Information |

|||

| Design: | Skid Mount/Containerised | Water Temp.: | 5~35˚C |

|---|---|---|---|

| PH: | 4~9 | TSS/mg/L: | <5 |

| Silt Density Index: | <3 | Free Chlorine Mg/L: | 0 |

| Dissolved Iron Mg/L: | <0.1 | Capacity: | 0.25-100m3/h |

| Voltage: | 380V,415V,220V,can Be Customized | Application: | Water Purification,Filtration,pharmceutical,drinking Water,food |

| Function: | Water Purifying, Filtration, Desalination | Desalination Rate: | 99%,99.7% |

| Control: | Electronic,Manual/PLC | Pump: | Booster, CNP / Grundfos,CNP |

| Highlight: | 90m3/H reverse osmosis system water waste,380V reverse osmosis system water waste,90m3/H ro waste water treatment |

||

Product Description

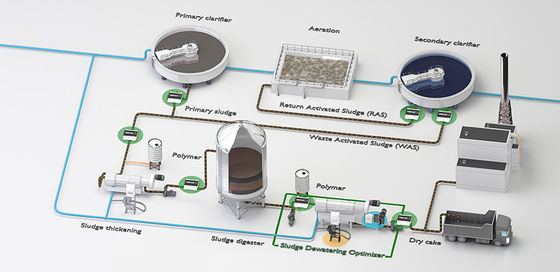

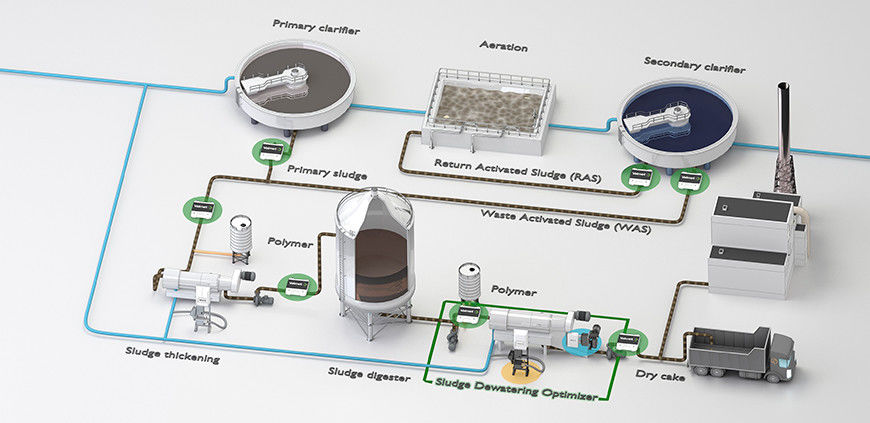

Wastewater treatment technologies of clarification, purification and sludge dewatering etc.

Wastewater treatment processes include processing technologies for separating physical, chemical and biological contaminants and pathogens from discarded wastewater; treating sludge and controlling aquatic odors to extract the full value from wastewater resources.

To do this, we provide wastewater treatment solutions for industrial wastewater treatment, municipal wastewater treatment for industry, wastewater treatment package plants, industry-specific wastewater treatment chemicals and technologies. These treatment solutions are available using different processes and methods depending on plant requirements.

Wastewater treatment processes include:

- Clarification and purification equipment supplies to wastewater treatment processing plants

- Production of drinking, pure and process water

- Decontamination of wastewater

- Recycling of treated wastewater and industrial effluents

- Reuse of treated sludge

- Recovery of valuable commodities from wastewater

Apart from recovered water, several by-products can be recycled from the wastewater treatment process. Solid, dewatered sludge produced during the wastewater treatment process has an inherently high nutrient content, which can be harnessed as an agricultural fertilizer.

Waste calories are also recovered in terms of their biogas content, creating more energy-neutral wastewater treatment process plants.

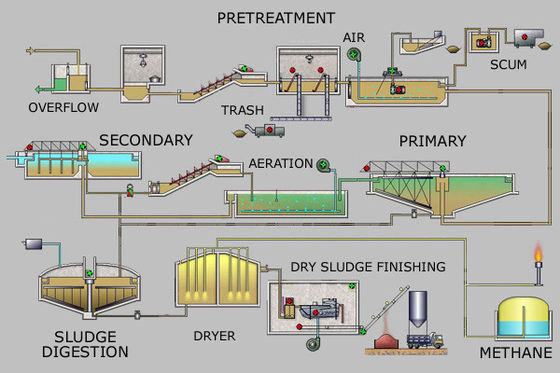

THE WASTEWATER TREATMENT PROCESS

Wastewater treatment process for the refinement of water content in all its forms - drinking water, industrial water, ultra-pure water, sewage and seawater:

- Biological treatment

- Membrane treatment: microfiltration, ultrafiltration, reverse osmosis

- Bio-membrane treatment

- Membrane desalination, thermal or hybrid

WASTEWATER TREATMENT SOLUTIONS

Our customized, cost-efficient solutions cover the complete wastewater treatment process:

- Pre-treatment

Contaminated effluent carried to a wastewater treatment is processed through a series of filters to remove large contaminants before proceeding through a finer filter mesh (<1 mm) for smaller object removal.

- Primary Treatment

Primary treatment is essentially a temporary and dormant state of holding wastewater, allowing heavier solid matter to sink, while oils, grease and lighter matters rise to the surface. The settled and floating matter is then removed to allow the remaining liquid to be undergo a secondary wastewater treatment process.

- Secondary Treatment

Secondary treatment involves the removal of dissolved and suspended biological matter from the liquid, achieved via membrane or media filtration or through a controlled habitat of water-borne micro-organisms.

- Tertiary Treatment & Reuse

In addition to using either chemical or physical disinfection, the tertiary wastewater treatment process brings water to a quality standard that will not harm a fragile, sensitive receiving environment.

Lamella Clarifier of conical bottom (without scraper) Specification

| Model | Capacity | Dimension(m) | Nozzle list(DN)GB/JIS/ANSL | |||||

| (m3/h) | L | W | H1/H2 | Inlet | Outlet | Sludge outlet | Backwash | |

| LC1-001 | ~1 | 1.6 | 0.8 | 2.0/2.0 | 25 | 25 | 50 | 50 |

| LC1-003 | ~3 | 1.6 | 1.1 | 2.0/2.0 | 50 | 50 | 50 | 50 |

| LC1-005 | ~5 | 2.6 | 1.6 | 2.9/2.9 | 80 | 50 | 50 | 50 |

| LC1-010 | ~10 | 3.4 | 1.8 | 3.6/1.8 | 100 | 80 | 50 | 50 |

| LC1-020 | ~20 | 3.4 | 2.2 | 3.6/1.8 | 150 | 100 | 50 | 50 |

| LC1-030 | ~30 | 4.2 | 2.2 | 4.0/2.2 | 150 | 150 | 50 | 50 |

| LC1-040 | ~40 | 5.3 | 2.2 | 3.6/1.8 | 200 | 150 | 50*2 | 50 |

| LC1-050 | ~50 | 6.3 | 2.2 | 3.8/2.0 | 200 | 200 | 50*2 | 50 |

| LC1-060 | ~60 | 7.2 | 2.2 | 4.0/2.2 | 250 | 200 | 50*2 | 50 |

| LC1-070 | ~70 | 7.2 | 2.6 | 4.0/2.2 | 250 | 200 | 50*2 | 50 |

| LC1-080 | ~80 | 7.2 | 2.7 | 4.0/2.2 | 250 | 200 | 80*2 | 50 |

| LC1-090 | ~90 | 6.7 | 3.1 | 4.0/2.2 | 250 | 250 | 80*2 | 50 |

| LC1-100 | ~100 | 7.2 | 3.1 | 4.0/2.2 | 250 | 250 | 80*2 | 50 |

| LC1-120 | ~120 | 8.3 | 3.3 | 4.0/2.2 | 250 | 250 | 80*2 | 50 |

| LC1-150 | ~150 | 9.8 | 3.3 | 4.0/2.2 | 250 | 250 | 80*2 | 50 |

Dissolved Air Floatation

| Model | Capacity | Power(kw) | Dimension(m) | Nozzle list(DN) | ||||||||

| (m^3/h) | Recirlation pump | Air compressor | Skimmer |

Coagulation mixer |

Flocclation mixer | L/L1 | W/W1 | H/H1 | Inlet | Outlet | Sludge scraper | |

| IDAF-002 | ~2 | 0.75 | 0.55 | 0.2 | 0.37 | 0.25 | 3.8/2.9 | 2.4/1.16 | 2.1/1.7 | 50 | 50 | 80 |

| IDAF-003 | ~3 | 0.75 | 0.55 | 0.2 | 0.37 | 0.25 | 4.1/3.2 | 2.4/1.16 | 2.1/1.7 | 50 | 50 | 100 |

| IDAF-005 | ~5 | 1.1 | 0.55 | 0.2 | 0.37 | 0.25 | 4.4/3.5 | 2.4/1.16 | 2.1/1.7 | 80 | 80 | 100 |

| IDAF-010 | ~10 | 1.5 | 0.55 | 0.2 | 0.37 | 0.25 | 5.0/3.9 | 2.92/1.66 | 2.3/1.9 | 100 | 100 | 100 |

| IDAF-015 | ~15 | 2.2 | 0.75 | 0.2 | 0.37 | 0.25 | 6.1/5.0 | 2.92/1.66 | 2.3/1.9 | 100 | 100 | 100 |

| IDAF-020 | ~20 | 3.0/5.5 | 0.75 | 0.2 | 0.37 | 0.25 | 6.2/5.1 | 3.1/2.16 | 2.3/1.9 | 150 | 100 | 100 |

| IDAF-030 | ~30 | 3.0/5.5 | 0.75 | 0.2 | 0.37 | 0.25 | 7.7/6.6 | 3.1/2.16 | 2.3/2.0 | 150 | 150 | 150 |

| IDAF-040 | ~40 | 3.0/5.5 | 0.75 | 0.2 | 0.75 | 0.37 | 7.9/6.7 | 3.6/2.7 | 2.7/2.3 | 200 | 150 | 150 |

| IDAF-050 | ~50 | 7.5 | 1.5 | 0.2 | 0.75 | 0.37 | 9.0/7.8 | 3.6/2.7 | 2.7/2.3 | 200 | 150 | 150 |

| IDAF-060 | ~60 | 7.5 | 1.5 | 0.2 | 0.75 | 0.37 | 9.3/8.1 | 4.0/3.0 | 2.7/2.3 | 250 | 200 | 150 |

| IDAF-070 | ~70 | 11 | 1.5 | 0.2 | 0.75 | 0.37 | 11.1/9.9 | 4.0/3.0 | 2.7/2.3 | 250 | 200 | 150 |

| IDAF-080 | ~80 | 11 | 1.5 | 0.2 | 1.5 | 0.37 | 11.7/10.4 | 4.0/3.0 | 2.7/2.3 | 250 | 200 | 150 |

| IDAF-100 | ~100 | 15 | 2.2 | 0.2 | 1.5 | 0.37 | 12.9/11.8 | 4.4/3.4 | 2.7/2.3 | 300 | 250 | 150 |

| IDAF-120 | ~120 | 15 | 2.2 | 0.2 | 1.5 | 0.37 | 13.9/12.8 | 4.4/3.4 | 2.7/2.3 | 300 | 250 | 150 |

| IDAF-150 | ~150 | 18.5 | 2.2 | 0.2 | 1.5 | 0.37 | 14.1/13.0 | 4.4/3.8 | 2.7/2.3 | 350 | 300 | 150 |

Sludge Treatment

Sludge, the solid component of wastewater refining, can be harvested for its nutritional component, thus limiting the ultimate volume of solid waste while generating an additional revenue stream to subsidise a plant's sewage water treatment costs.

| Model | Size(L*W*H)/mm | Power(KW) | Weight(Kg) |

| BEA-131 | 1816×750×1040 | 0.35KW | 194Kg |

| BEA-132 | 2065×900×1040 | 0.45KW | 275Kg |

| BEA-201 | 2500×680×1450 | 0.74KW | 380Kg |

| BEA-202 | 2500×930×1450 | 1.1KW | 470Kg |

| BEA-301 | 3200×970×1790 | 0.92KW | 820Kg |

| BEA-302 | 3600×1200×1790 | 1.65KW | 1350Kg |

| BEA-303 | 3850×1600×1790 | 2.2KW | 1820Kg |

| BEA-351 | 4000×750×2000 | 1.3KW | 950Kg |

| BEA-352 | 4200×1200×2000 | 2.25KW | 1300Kg |

| BEA-353 | 4350×1700×2000 | 3.35KW | 1680Kg |

| BEA-401 | 4200×850×2100 | 2.05KW | 1270Kg |

| BEA-402 | 4350×1450×2100 | 3.75KW | 2350Kg |

| BEA-403 | 4500×2050×1960 | 5.6KW | 3870Kg |

| BEA-404 | 4600×2250×1960 | 8.2KW | 5230Kg |

MBR - Membrane Bioreactor Specifications:

|

Type size |

Treatment capacity |

Membrane size |

Qty (pcs) |

Module (units) |

Total Installed power |

Operating power (KW) |

Tank size(mm) | No.s of tank |

| MBR-25 | 25 m³/d | PURE-100 | 80 | 1 | 7.8 | 3.35 | 9000*2400*2500 | 1 |

| MBR-40 | 40 m³/d | PURE-100 | 100 | 1 | 7.8 | 3.35 | 7000*2400*2500 | 1 |

| MBR-50 | 50 m³/d | PURE-100 | 160 | 2 | 9.75 | 5.25 | 9000*2400*2500 | 1 |

| MBR-80 | 80 m³/d | PURE-100 | 200 | 2 | 13.8 | 5.25 | 10000*2400*2500 | 1 |

| MBR-100 | 100 m³/d | PURE-100 | 140 | 3 | 19.9 | 10.7 | 10000*2400*2500 | 1 |

| MBR-120 | 120 m³/d | PURE-100 | 300 | 3 | 21.75 | 13.55 | 10000*2400*2500 | 1 |

| MBR-160 | 160 m³/d | PURE-100 | 400 | 4 | 27.75 | 16.55 | 12000*2400*2500 | 1 |

| MBR-200 | 200 m³/d | PURE-100 | 500 | 5 | 30.85 | 18.25 | 7000*2400*2500 | 2 |

| MBR-240 | 240 m³/d | PURE-100 | 600 | 6 | 38.9 | 23.2 | 8500*2400*2500 | 2 |

| MBR-320 | 320 m³/d | PURE-100 | 800 | 8 | 38.9 | 23.2 | 10000*2400*2500 | 2 |

| MBR-400 | 400 m³/d | PURE-100 | 1000 | 10 | 30.35 | 15.75 | 11500*2400*2500 | 2 |

| MBR-480 | 480 m³/d | PURE-100 | 1200 | 12 | 33.65 | 15.9 |

13500*2400*2500 12000*2400*2500 |

1 1 |

| MBR-560 | 560 m³/d | PURE-100 | 1400 | 14 | 43.85 | 21 | 8500*2400*2500 | 3 |

| MBR-640 | 640 m³/d | PURE-100 | 1600 | 16 | 41.85 | 20 | 11500*2400*2500 | 3 |

| MBR-720 | 720 m³/d | PURE-100 | 1800 | 18 | 54.85 | 26 | 12000*2400*2500 | 3 |

![]()

![]()