1500GPD Purified Water System In Pharmaceutical Industry

Product Details:

| Place of Origin: | China |

| Brand Name: | Fenigal/OEM |

| Certification: | CE/NSF etc. |

| Model Number: | WTS-14 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 Set |

|---|---|

| Price: | Negotiable |

| Packaging Details: | Standard Export Wood Crate/Carton or Naked wrapped by film |

| Delivery Time: | 15~30 days |

| Payment Terms: | T/T, Western Union, Paypal etc. |

| Supply Ability: | 200 set per month |

|

Detail Information |

|||

| Technology: | Pretreatment+Reverse Osmosis/UF/NF Etc. | Design: | Skid Mount/Containerised |

|---|---|---|---|

| Permeate Flow/TPD: | 0.25~1000 | Permeate Flow/GPD: | 1,679~263,158 |

| Recovery Rate: | 40~70% | Feed TDS/ppm: | <2,000 |

| Water Temp.: | 5~35˚C | PH: | 4~9 |

| TSS/mg/L: | <5 | Silt Density Index: | <3 |

| Free Chlorine Mg/L: | 0 | Dissolved Iron Mg/L: | <0.1 |

| Warranty: | 1 Year | Material: | SS304/SS316L,carbon Steel |

| Capacity: | 0.25-100m3/h | Voltage: | 380V,415V,220V,can Be Customized |

| Application: | Water Purification,Filtration,pharmceutical,drinking Water,food | Size: | 1750*550*1650mm Smaller Or Bigger |

| Type: | Water Treatment Plant System | Function: | Water Purifying, Filtration, Desalination |

| Desalination Rate: | 99%,99.7% | Control: | Electronic,Manual/PLC |

| Ro Membrane: | Vontron, Hydranautics Or DOW, 4040/8040 | Pump: | Booster, CNP / Grundfos,CNP |

| Highlight: | 1500GPD purified water system in pharmaceutical industry,SS316L purified water system in pharmaceutical industry,1500GPD pharmaceutical water system |

||

Product Description

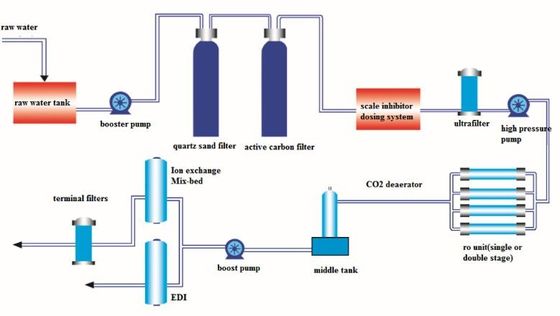

Pharmaceutical Water Treatment Systems with Double Pass Reverse Osmosis and/or EDI

Pharmaceutical water treatment is required since applications within the drug industry are highly complex and essential in producing the medicines that save millions and millions of lives around the world.

Our Pharmaceutical Water Treatment Solutions Include:

- Water Disinfection Systems

- Water Softener Systems

- DI Water System

- Industrial Ultrafiltration

Unlike other industries, water is mainly used in liquid form (or a cleaning agent) within the pharmaceutical industry, and not only as an ingredient. We have made it imperative to produce highly distilled water, disease-free water, and water for injection to international pharmaceutical standards. As our knowledge of our client’s needs grew, so did our efficiency in developing high-quality pharmaceutical water treatment systems.

Our reverse osmosis systems feature an optional dual probe comparative monitor, which specifically analyzes the membrane’s performance and notifies us when the membrane is ready to be displaced. This accurate level of assessment regarding the monitoring of your rejection water quality will leave you satisfied at the touch of a button.

Double Pass Ultrapure Reverse Osmosis Systems are designed for a variety of industrial applications requiring high quality equipment with fast delivery and competitive prices. These pre-engineered, assembled and factory tested systems feature easy-to-set controls that minimize installation and start-up times and allow for quick online service. DPRO Systems serve process water generation industries that need ultrapure water, such as Power Generation, General Industry, Food and Beverage, Cosmetics, Pharmaceutical and Microelectronics.

| Models | DP – 1500 | DP – 2000 | DP – 3000 | DP – 4000 |

| Flow Rates | ||||

| Permeate Flow Rate (gpd) | 1500 | 2000 | 3000 | 4000 |

| Permeate Flow Rate (gpm) | 1.04 | 1.38 | 2.08 | 2.7 |

| Feedwater† TDS max (ppm) | 2000 | 2000 | 2000 | 2000 |

| Standard Recovery (%) | 26 | 31.5 | 39 | 43.8 |

| Minimum Concentrate Flow Rate (gpm) | Pass 1 – 3 Pass 2 – 0.5 | Pass 1 – 3 Pass 2 – 0.5 | Pass 1 – 3 Pass 2 – 1 | Pass 1 – 3 Pass 2 – 1 |

| Connections | ||||

| Feed Connection (in) | 1 FNPT | 1 FNPT | 1 FNPT | 1 FNPT |

| Permeate Connection (in) | 1/2 FNPT | 1/2 FNPT | 3/4 FNPT | 3/4 FNPT |

| Concentrate Connection (in) | 1/2 FNPT | 1/2 FNPT | 3/4 FNPT | 3/4 FNPT |

| Membranes | ||||

| Membrane(s) Per Vessel | 1 | 1 | 1 | 1 |

| Membrane Quantity | 4 | 5 | 4 | 5 |

| Membrane Size | 2 – 4040 / 2 – 2540 | 2 – 4040 / 3 – 2540 | 3 – 4040 / 1 – 4040 | 3 – 4040 / 2 – 4040 |

| Nominal TDS Rejection % | 99.9 | 99.9 | 99.9 | 99.9 |

| Vessels | ||||

| Vessel Array | Pass 1 – 1:1 Pass 2 – 1:1 | Pass 1 – 1:1 Pass 2 – 1:1:1 | Pass 1 – 1:1:1 Pass 2 – 1 | Pass 1 – 1:1:1 Pass 2 – 1:1 |

| Vessel Quantity | 2 – 4040 / 2 – 2540 | 2 – 4040 / 3 – 2540 | 3 – 4040 / 1 – 4040 | 3 – 4040 / 2 – 4040 |

| Pumps | ||||

| Pump Type | Multi–Stage | Multi–Stage | Multi–Stage | Multi–Stage |

| Motor HP | 1.5 / .75 | 1.5 / .75 | 1.5 / .75 | 1.5 / 1.5 |

| RPM at 60 Hz | 3450 | 3450 | 3450 | 3450 |

| System Electrical | ||||

| Standard Voltage + Amp Draw | 220V, 60Hz, 16 | 220V, 60Hz, 16 | 220V, 60Hz, 16 | 220V, 60Hz, 19 |

| System Dimensions | ||||

| Approximate Dimensions* L x W x H (in) | 26 x 26 x 60 | 26 x 26 x 60 | 26 x 26 x 60 | 26 x 26 x 60 |

| Approximate Weight (lbs) | 330 | 335 | 320 | 340 |

Warranty Evaluation Test Conditions: Permeate flow rates and salt rejection based on the following test conditions – 550 ppm, filtered and dechlorinated municipal tap water, 77°F / 25°C, 15% recovery, 7.0 pH and the specified operating pressure for membrane element type. Data taken after 60 minutes of operation

* Does not include operating space requiremen

Why are Double Pass RO Systems Beneficial?

Climate change has caused many parts of the world to experience droughts, so there is always concern about conserving water and maximizing a system's recovery (water efficiency) of waste water. Traditional single pass RO systems achieve approximately 75% efficiency, while double pass RO can achieve an efficiency of 90% or more. In addition, this method of designing a reverse osmosis system can also be beneficial for the production of high purity permeate water for high purity and ultrapure water applications. Other water treatment technologies such as electrodeionization (EDI) or mixed bed deionization (MBDI) may be utilized in order to obtain similar water quality levels.

![]()

![]()

![]()

![]()