Mining Industry RO Purified Water Treatment System

Product Details:

| Place of Origin: | China |

| Brand Name: | Fenigal/OEM |

| Certification: | CE/NSF etc. |

| Model Number: | WTS-13 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 Set |

|---|---|

| Price: | Negotiable |

| Packaging Details: | Standard Export Wood Crate/Carton or Naked wrapped by film |

| Delivery Time: | 15~30 days |

| Payment Terms: | T/T, Western Union, Paypal etc. |

| Supply Ability: | 200 set per month |

|

Detail Information |

|||

| Technology: | Pretreatment+Reverse Osmosis/UF/NF Etc. | Design: | Skid Mount/Containerised |

|---|---|---|---|

| Feed TDS/ppm: | <2,000 | Water Temp.: | 5~35˚C |

| TSS/mg/L: | <5 | Silt Density Index: | <3 |

| Dissolved Iron Mg/L: | <0.1 | Voltage: | 380V,415V,220V,can Be Customized |

| Application: | Water Purification,Filtration,pharmceutical,drinking Water,food | Function: | Water Purifying, Filtration, Desalination |

| Desalination Rate: | 99%,99.7% | Control: | Electronic,Manual/PLC |

| Highlight: | 220V Purified Water Treatment System,OEM Purified Water Treatment System,220V mine water treatment plant |

||

Product Description

Water Treatment Systems For The Mining Industry Reverse Osmosis

MEMBRANE SYSTEMS

Possibly the greatest issue with mining comes from waste. Mining for metals and salts commonly produces tons of waste per product, and often this waste is comprised of acidic materials that can affect the surrounding environment or permanently reduce a natural water source to toxic levels. Membrane Systems can be specifically designed to meet any water purification need, drastically reducing the amount of waste produced in large-scale mining operations and preventing this waste from ever being exposed to the surrounding environment. Much of this purified water can also be reused in the same mining operation, lowering the toll it takes on local water sources. It also provides a good source of water for on-site domestic uses as well (showers, sinks, restrooms, etc.).

ULTRAFILTRATION SYSTEMS

The mining of metals produces a specific kind of waste known as tailings, which have been the source of at least one mining disaster a year, on average, worldwide. Tailings are a form of slurry, consisting of waste materials in high concentrations dissolved in water, making a kind of sludge that is not only hazardous to the environment, but unsightly and difficult to dispose of, often remaining in large ponds for decades as heavy materials seep to the bottom and the water evaporates. Among the hazardous chemicals in tailings is arsenic (in gold mining), cyanide, sulfuric acid, and a number of known carcinogens. A breakthrough technology using high-pressure membrane systems allows the condensing of tailings into large blocks, which can be stacked to reduce footprint and no longer pose the risk of seepage into natural water sources.

MINING INDUSTRY SOLUTIONS

As a complete system integrator, Pure Aqua has a wide range of solutions for the mining section, specifically:

1. Packaged Drinking Water Plants

2. Effluent polishing to meet discharge requirements (i.e. selenium)

3. Treating industrial process water in general

Industrial Ultrafiltration UF Systems

| Model No. | Capacity - Surface Water | Capacity - Seawater | Capacity - Ground Water | ||||

| Flux at 25 GFD | Flux at 35 GFD | Flux at 53 GFD | Qty of | ||||

| GPD | M3/ Day | GPD | M3/ Day | GPD | M3/ Day | UF Modules | |

| UF-400-10 | 105,263 | 400 | 158,038 | 599 | 258,608 | 980 | 10 |

| UF-480-12 | 126,316 | 480 | 190,623 | 722 | 311,929 | 1,182 | 12 |

| UF-640-16 | 168,421 | 640 | 254,164 | 963 | 415,905 | 1,575 | 16 |

| UF-800-20 | 210,526 | 800 | 316,076 | 1,197 | 517,215 | 1,959 | 20 |

| UF-1040-26 | 273,684 | 1040 | 412,202 | 1,561 | 674,512 | 2,555 | 26 |

| UF-1200-30 | 315,789 | 1,200 | 475,743 | 1,802 | 778,489 | 2,949 | 30 |

| UF-1600-40 | 421,053 | 1,600 | 633,781 | 2,401 | 1,037,096 | 3,928 | 40 |

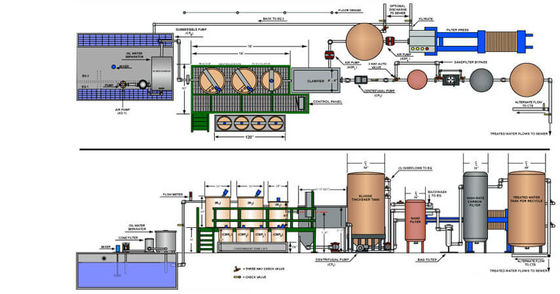

Containerized seawater treatment plant in 20' or 40' for mobile water supply

Applications

Power or Chemical Plants

Offshore platforms

Island residents

Hotels, resorts

Construction sites

| Technical Data | Unit |

A20

C20 |

A50

C50 |

A80

C80 |

A100

C100 |

A150

C150 |

| Rated Product Flow 1) | M3/H | 0.8 | 2.3 | 3.5 | 4.5 | 6.5 |

| Rated Recovery Rate 1) | % | 34 | 34 | 34 | 34 | 34 |

| Min Pressure In2) | barg | 4 | 4 | 4 | 4 | 4 |

| Max Pressure In 2) | barg | 6 | 6 | 6 | 6 | 6 |

| Min System Pressure3) | barg | 20 | 20 | 20 | 20 | 20 |

| Max System Pressure3) | barg | 70 | 70 | 70 | 70 | 70 |

| RO Membrane Spec. | inch | 4040 | 8040 | 8040 | 8040 | 8040 |

| RO Membrane Qty. | pcs | 6 | 4 | 6 | 8 | 12 |

| Container size (qty) | ft | 10 | 10 | 20 | 20 | 20 |

| Weight (dry) 4) | ton | 3 | 3 | 5 | 6 | 7 |

| Rated Power5) | kW | 5 | 17 | 25 | 32 | 44 |

| Power Input 6) | 3PH, 380 AC±10%, 50Hz | |||||

![]()