7.5KW Purified Water Treatment System , Boiler Feed Water Treatment Plant

Product Details:

| Place of Origin: | China |

| Brand Name: | Fenigal/OEM |

| Certification: | CE/UL/NSF etc. |

| Model Number: | WTS-6 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 Set |

|---|---|

| Price: | Negotiable |

| Packaging Details: | Standard Export Wood Crate/Carton or Naked wrapped by film |

| Delivery Time: | 15~30 days |

| Payment Terms: | T/T, Western Union, Paypal etc. |

| Supply Ability: | 200 set per month |

|

Detail Information |

|||

| Technology: | Pretreatment+Reverse Osmosis+IX Etc. | Permeate Flow/TPD: | 0.25~1000 |

|---|---|---|---|

| Recovery Rate: | 40~70% | Feed TDS/ppm: | <2,000 |

| Water Temp.: | 5~35˚C | PH: | 4~9 |

| TSS/mg/L: | <5 | Silt Density Index: | <3 |

| Free Chlorine Mg/L: | 0 | Dissolved Iron Mg/L: | <0.1 |

| Material: | SS304/SS316L,carbon Steel | Capacity: | 0.25-100m3/h |

| Voltage: | 380V,415V,220V,can Be Customized | Application: | Water Purification,Filtration,pharmceutical,drinking Water,food |

| Control: | Electronic,Manual/PLC | Ro Membrane: | Vontron, Hydranautics Or DOW, 4040/8040 |

| Highlight: | 7.5KW 2000ppm Purified Water Treatment System,7.5KW Purified Water Treatment System,SS316L boiler feed water treatment plant |

||

Product Description

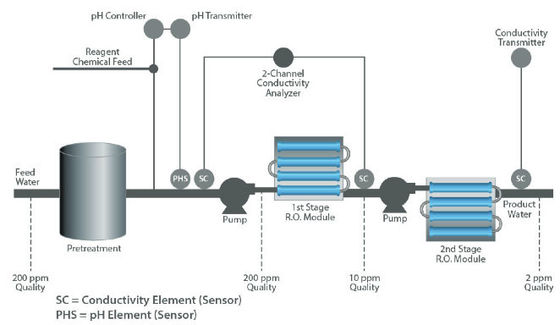

Boiler Feed Water Treatment Plant Reverse Osmosis and Ion exchange demineralized process

Boiler feed water treatment plants utilize several contaminants that remove are hardness, iron, silica, sodium and chlorides. The basic process removes the suspended matter before reverse osmosis (dissolved solids reduction) and finally EDI polishing. RO pre-treatment commonly consists of coagulation, flocculation, clarification, sand filtration, etc. Essentially 100% of the suspended particles must be removed in the pre-treatment. RO removes approximately 99+% of dissolved salts and solids in water.

Our water treatment technologies employed for the boiler feed solutions Include:

- Nano Filtration Systems

- Reverse Osmosis Systems

- Water Softener

- DI Water System

- Industrial Filtration Systems

BOILER FEED WATER PURIFICATION PROCESS

EDI is the final polisher. Continuous Electrodeionization (CEDI or EDI) is a process that uses electricity to produce ultra-pure deionized/demineralized water. While it utilizes ion exchange resin, it is continuously self-regenerated without the use of chemicals (i.e. caustic and acid used with conventional ion exchange systems).

THERE ARE A NUMBER OF ADVANTAGES TO EDI SYSTEM VERSUS MIXED BED (IX):

- Easier to obtain permits

- Green technology – chemical free process

- Lower operating costs

- No hazardous waste (no neutralization sump/system required)

- No handling, disposal, or storage issues/concerns

- Safer

- Smaller footprint/space requirement

| Models | TX/BX – 2280 | TX/BX – 3280 | TX/BX – 4280 | TX/BX – 5280 | TX/BX – 3480 | TX/BX – 4480 | TX/BX – 5480 | TX/BX – 6480 | ||

| Design | ||||||||||

| Configuration | Single Pass | Single Pass | Single Pass | Single Pass | Single Pass | Single Pass | Single Pass | Single Pass | ||

| Feedwater Source† | TDS | TDS | TDS | TDS | TDS | TDS | TDS | TDS | ||

| <2,000 ppm | <2,000 ppm | <2,000 ppm | <2,000 ppm | <2,000 ppm | <2,000 ppm | <2,000 ppm | <2,000 ppm | |||

| Standard Recovery % | 61 | 70 | 75 | 75 | 75 | 75 | 75 | 75 | ||

| Recovery with Concentrate | 80 | 80 | 80 | N/A | N/A | N/A | N/A | N/A | ||

| Recycle gpm % | ||||||||||

| Rejection and Flow Rates ††† | ||||||||||

| Nominal Salt Rejection % | 99 | 99 | 99 | 99 | 99 | 99 | 99 | 99 | ||

| Permeate Flow Rate | 22.00 / | 33.00 / | 44.00 / | 55.00 / | 66.00 / | 88.00 / | 110.00 / | 132.00 / | ||

| (gpm / lpm) | 83 | 125 | 167 | 208 | 250 | 333 | 416 | 500 | ||

| Minimum Concentrate | 14 / 53 | 14 / 53 | 14.6 / 55 | 18.3 / 69 | 22 / 83 | 29 / 111 | 36.6 / 139 | 44 / 167 | ||

| Flow Rate (gpm / lpm) | ||||||||||

| Connections | ||||||||||

| Feed Connection (in) | 2 FNPT | 2 FNPT | 2 FNPT | 2 FNPT | 3 FNPT | 3 FNPT | 3 FNPT | 3 FNPT | ||

| Permeate Connection (in) | 1 1/2 FNPT | 1 1/2 FNPT | 2 FNPT | 2 FNPT | 2 1/2 FNPT | 2 1/2 FNPT | 3 FNPT | 3 FNPT | ||

| Concentrate Connection (in) | 1 1/4 FNPT | 1 1/4 FNPT | 1 1/4 FNPT | 1 1/4 FNPT | 1 1/2 FNPT | 1 1/2 FNPT | 2 FNPT | 2 FNPT | ||

| Clean–in–Place Port (in) | 1 1/2 FNPT | 1 1/2 FNPT | 1 1/2 FNPT | 1 1/2 FNPT | 2 FNPT | 2 FNPT | 2 FNPT | 2 FNPT | ||

| Chemical Feed Port (in) | 1/2 NPT | 1/2 NPT | 1/2 NPT | 1/2 NPT | 1/2 NPT | 1/2 NPT | 1/2 NPT | 1/2 NPT | ||

| Membranes | ||||||||||

| Membrane(s) Per Vessel | 2 | 2 | 2 | 2 | 4 | 4 | 4 | 4 | ||

| Membrane Quantity | 4 | 6 | 8 | 10 | 12 | 16 | 20 | 24 | ||

| Membrane Size | 8040 | 8040 | 8040 | 8040 | 8040 | 8040 | 8040 | 8040 | ||

| Vessels | ||||||||||

| Vessel Array | 1:01 | 1:01:01 | 1:1:1:1 | 2:1:1:1 | 2:01 | 2:01:01 | 3:01:01 | 3:02:01 | ||

| Vessel Quantity | 2 | 3 | 4 | 5 | 3 | 4 | 5 | 6 | ||

| Pumps | ||||||||||

| Vertical | Vertical | Vertical | Vertical | Vertical | Vertical | Vertical | Vertical | |||

| Pump Type | Multi–Stage | Multi–Stage | Multi–Stage | Multi–Stage | Multi–Stage | Multi–Stage | Multi–Stage | Multi–Stage | ||

| Centrifugal Pump | Centrifugal Pump | Centrifugal Pump | Centrifugal Pump | Centrifugal Pump | Centrifugal Pump | Centrifugal Pump | Centrifugal Pump | |||

| Motor HP / KW | 10 / 7.5 | 10 / 7.5 | 10 / 7.5 | 10 / 7.5 | 15 / 11 | 15 / 11 | 20 / 11 | 20 / 11 | ||

| System Electrical | ||||||||||

| Standard Voltage | 208V – 230V, | 208V – 230V, | 208V – 230V, | 208V – 230V, | 208V – 230V, | 208V – 230V, | 208V – 230V, | 208V – 230V, | ||

| + Amp Draw | 60Hz, 3PH, | 60Hz, 3PH, | 60Hz, 3PH, | 60Hz, 3PH, | 60Hz, 3PH, | 60Hz, 3PH, | 60Hz, 3PH, | 60Hz, 3PH, | ||

| 28A – 27A** | 28A – 27A** | 28A – 27A** | 28A – 27A** | 40.5A – 37A** | 40.5A – 37A** | 49A** | 49A** | |||

| Systems Dimensions | ||||||||||

| Approximate Dimensions* L x W x H (in / cm) | 112 x 35 x 74 / | 112 x 35 x 74 / | 112 x 35 x 74 / | 112 x 35 x 74 / | 194 x 41 x 78 / | 194 x 41 x 78 / | 194 x 41 x 78 / | 194 x 41 x 84 / | ||

| 284 x 89 x 188 | 284 x 89 x 188 | 284 x 89 x 188 | 284 x 89 x 188 | 493 x 104 x 198 | 493 x 104 x 198 | 493 x 104 x 198 | 493 x 104 x 213 | |||

| Approximate Weight | 1,285 / 583 | 1,435 / 651 | 1,585 / 719 | 1,735 / 787 | 2,005 / 910 | 2,275 / 1,032 | 2,645 / 1,200 | 2,910 / 1,320 | ||

![]()

![]()