900000 GPD Reverse Osmosis Systems For Agriculture

Product Details:

| Place of Origin: | China |

| Brand Name: | Fenigal/OEM |

| Certification: | CE/UL/NSF etc. |

| Model Number: | WTS-8 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 Set |

|---|---|

| Price: | Negotiable |

| Packaging Details: | Standard Export Wood Crate/Carton or Naked wrapped by film |

| Delivery Time: | 15~30 days |

| Payment Terms: | T/T, Western Union, Paypal etc. |

| Supply Ability: | 200 set per month |

|

Detail Information |

|||

| Technology: | Pretreatment+Reverse Osmosis/UF/NF Etc. | Design: | Skid Mount/Containerised |

|---|---|---|---|

| Feed TDS/ppm: | <2,000 | Water Temp.: | 5~35˚C |

| PH: | 4~9 | TSS/mg/L: | <5 |

| Silt Density Index: | <3 | Material: | SS304/SS316L,carbon Steel |

| Capacity: | 0.25-100m3/h | Voltage: | 380V,415V,220V,can Be Customized |

| Application: | Water Purification,Filtration,pharmceutical,drinking Water,food | Function: | Water Purifying, Filtration, Desalination |

| Desalination Rate: | 99%,99.7% | Control: | Electronic,Manual/PLC |

| Ro Membrane: | Vontron, Hydranautics Or DOW, 4040/8040 | Pump: | Booster, CNP / Grundfos,CNP |

| Highlight: | 900000GPD reverse osmosis systems for agriculture,415V reverse osmosis systems for agriculture,900000GPD agricultural water treatment systems |

||

Product Description

Agriculture | Reverse Osmosis & Water Treatment Systems 600 GPD to 900,000 GPD

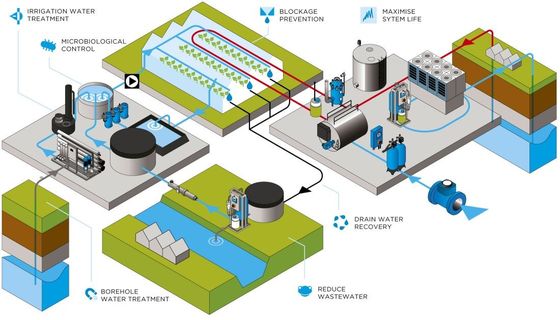

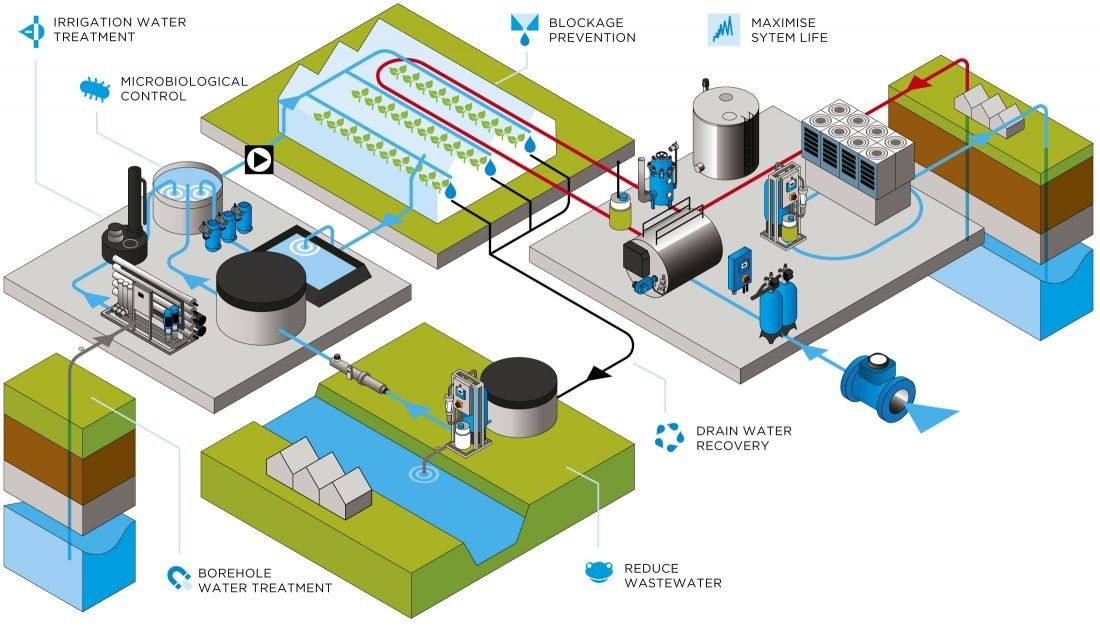

Our water treatment technologies employed for the Agriculture markets include:

- Ultrafiltration Systems

- Water Disinfection Systems

- Nanofiltration Systems

- Reverse Osmosis Systems

- Biological Treatment

IRRIGATION MEMBRANES & ULTRAFILTRATION

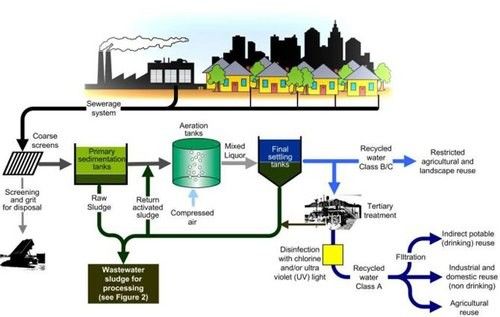

Due to plants and vegetables already consisting of natural filtration means that allow for much more non-stringent agricultural water treatment requirements for irrigation. For this reason, irrigation has a greater fill of resources to utilize compared to scarce groundwater resources. Irrigation primarily relies on practices that depend on making reuses of grey water, in addition to treated sewage effluent (TSE). These practices create wastewater, which is seen as a terrible source for drinking water, but perfectly suited for irrigation and farming once undergoing a reverse osmosis system. Many farms have resorted to only using these effective tactics for their water, and completely eliminated the use of underground aquifers.

Almost all naturally occurring water contains some form of contaminants from the surrounding rocks and soil that make up the earths crust. Drained irrigation water and effluent sewage water are contributors to the quality of water. Typically, salinity level is the main concern in the irrigation industry due to the debilitating effect salt has on soil and product growth. However, there are also other contaminants like boron that can be just as harmful to the irrigation industry due its similar adverse effects. Elevated amounts of boron cause toxicity effects to occur which causes damage to the soil and overall product yield. These high amounts can already exist naturally in groundwater and seawater but can also be a result of contaminated water.

The following systems complement the applications of hydroponics, commercial farmers, greenhouses, and pharmaceutical industries. These systems also tackle the issues of bacteria & viruses, reduction of chloride, sulfate, sodium, nitrate, arsenic, and overall TDS.

INDUSTRIAL/COMMERCIAL REVERSE OSMOSIS SYSTEM FEATURES:

- Capacity availability (ranges from 600 GPD to 900,000 GPD in capacity)

- Purifies water to result in 97% TDS rejection

- Removes 99% of contaminants

- Reduces:

- Hardness

- Nitrate

- Sulfate

- Sodium Chloride

- Heavy metals

- Applications that would relate to this system are:

Agriculture, Hydroponics, Aquaculture, Greenhouses, and Livestock Drinking water.

INDUSTRIAL/COMMERCIAL NANOFILTRATION SYSTEM FEATURES:

- Capacity availability (ranges from 600 GPD to 900,000 GPD in capacity)

- Reduces costs of operations

- Saves energy

- Softens water (tackles hardness)

- Removes bacteria & viruses

- Reduces:

- Total dissolved solids (TDS)

- Color + Turbidity

- Nitrates

- Sulfates

- Chlorine/Fluoride

- Pesticides + Herbicides + Insecticides

- Sodium + Chloride

- Applications that would directly benefit from this system are:

Hydroponics, Aquaculture, Agriculture, Greenhouses, and Livestock Drinking water.

INDUSTRIAL/COMMERCIAL MEDIA FILTRATION FEATURES:

- Capacity availability (ranges from 600 GPD to 500,000 GPD in capacity)

- Filters well water

- Embedded backwashing cycles

- Available manual control

- Reduces:

- Iron

- Manganese

- Hydrogen Sulfide + sulfur odors

- Sediment

- Applications that would relate to this system are:

Irrigation, Agriculture, Hydroponics, Greenhouses, Aquaculture, and Livestock Drinking water.

Product Specifications

| Models | HX – 2280 | HX – 3280 | HX – 4280 | HX – 5280 | HX – 3480 | HX – 4480 | HX – 5480 | HX – 6480 |

| Design | ||||||||

| Configuration | Single Pass | Single Pass | Single Pass | Single Pass | Single Pass | Single Pass | Single Pass | Single Pass |

| Feedwater TDS max (ppm)† |

7,000 | 7,000 | 7,000 | 7,000 | 7,000 | 7,000 | 7,000 | 7,000 |

| Standard Recovery % | 58 | 70 | 73 | 73 | 73 | 70 | 70 | 73 |

| Rejection and Flow Rates ††† | ||||||||

| Nominal Salt Rejection % | 99.8 | 99.8 | 99.8 | 99.8 | 99.8 | 99.8 | 99.8 | 99.8 |

| Permeate Flow Rate (gpm / lpm) |

21.00 / 79.50 |

31.50 / 119.00 |

42.00 / 159.00 |

52.50 / 198.70 |

63.00 / 238.40 |

84.00 / 318.00 |

105.00 / 397.00 |

126.00 / 477.00 |

| Minimum Concentrate Flow Rate (gpm / lpm) |

15 / 57 | 13.5 / 51 | 15.3 / 58 | 19.42 / 73.51 | 23.3 / 88.20 | 36 / 136 | 45 / 170 | 46.6 / 176.40 |

| Connections | ||||||||

| Feed Connection (in) | 2 FNPT | 2 FNPT | 2 FNPT | 2 FNPT | 3 FNPT | 3 FNPT | 3 FNPT | 3 FNPT |

| Permeate Connection (in) | 1 1/2 FNPT | 1 1/2 FNPT | 2 FNPT | 2 FNPT | 2 1/2 FNPT | 2 1/2 FNPT | 3 FNPT | 3 FNPT |

| Concentrate Connection (in) | 1 1/4 FNPT | 1 1/4 FNPT | 1 1/4 FNPT | 1 1/4 FNPT | 1 1/2 FNPT | 1 1/2 FNPT | 2 FNPT | 2 FNPT |

| Clean–in–Place Port (in) | 1 1/2 FNPT | 1 1/2 FNPT | 1 1/2 FNPT | 1 1/2 FNPT | 2 FNPT | 2 FNPT | 2 FNPT | 2 FNPT |

| Chemical Feed Port (in) | 1/2 NPT | 1/2 NPT | 1/2 NPT | 1/2 NPT | 1/2 NPT | 1/2 NPT | 1/2 NPT | 1/2 NPT |

| Membranes | ||||||||

| Membrane(s) Per Vessel | 2 | 2 | 2 | 2 | 4 | 4 | 4 | 4 |

| Membrane Quantity | 4 | 6 | 8 | 10 | 12 | 16 | 20 | 24 |

| Membrane Size | 8040 | 8040 | 8040 | 8040 | 8040 | 8040 | 8040 | 8040 |

| Vessels | ||||||||

| Vessel Array | 1:1 | 1:1:1 | 2:1:1 | 2:1:1:1 | 2:1 | 2:1:1 | 3:1:1 | 3:2:1 |

| Vessel Quantity | 2 | 3 | 4 | 5 | 3 | 4 | 5 | 6 |

| Pumps | ||||||||

| Pump Type | Vertical Multi–Stage Centrifugal Pump | Vertical Multi–Stage Centrifugal Pump | Vertical Multi–Stage Centrifugal Pump | Vertical Multi–Stage Centrifugal Pump | Vertical Multi–Stage Centrifugal Pump | Vertical Multi–Stage Centrifugal Pump | Vertical Multi–Stage Centrifugal Pump | Vertical Multi–Stage Centrifugal Pump |

| Motor HP / KW | 15 / 11 | 15 / 11 | 25 / 19 | 25 / 19 | 25 / 19 | 40 / 30 | 40 / 30 | 50 / 37 |

| System Electrical | ||||||||

| Standard Voltage + Amp Draw |

460V, 60Hz, 3PH, 19A** |

460V, 60Hz, 3PH, 19A** |

460V, 60Hz, 3PH, 31A** |

460V, 60Hz, 3PH, 31A** |

460V, 60Hz, 3PH, 31A** |

460V, 60Hz, 3PH, 48.5A** |

460V, 60Hz, 3PH, 48.5A** |

460V, 60Hz, 3PH, 58.5A** |

| Systems Dimensions | ||||||||

| Approximate Dimensions* L x W x H (in / cm) | 112 x 35 x 74 / 284 x 89 x 188 |

112 x 35 x 74 / 284 x 89 x 188 |

112 x 35 x 74 / 284 x 89 x 188 |

112 x 35 x 84 / 284 x 89 x 213 |

194 x 41 x 78 / 493 x 104 x 198 |

194 x 41 x 78 / 493 x 104 x 198 |

194 x 41 x 78 / 493 x 104 x 198 |

194 x 41 x 84 / 493 x 104 x 213 |

| Approximate Weight (lbs / kg) |

2130 / 970 | 2450 / 1110 | 3040 / 1380 | 3340 / 1520 | 4100 / 1860 | 4490 / 2040 | 5280 / 2400 | 5640 / 2560 |

Test Parameters: 7000 TDS Filtered (5 – Micron), Dechlorinated, Municipal Feedwater, 65 psi / 4.50 bar Feed Pressure, 350 psi / 24 bar Operating Pressure, 77ªF / 25ªC, Recovery as stated, 7.0 pH. Data taken after 60 minutes of operation.

* Does not include operating space requirements.

** Varies with motor manufacturer.

![]()