DuPont AmberLite HPR4200 Cl Ion Exchange Resin for Industrial Water Demineralization with Whole Uncracked Beads ≥ 90% and Swelling 20%

Product Details:

| Place of Origin: | China |

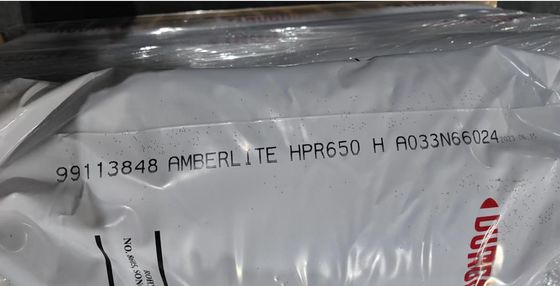

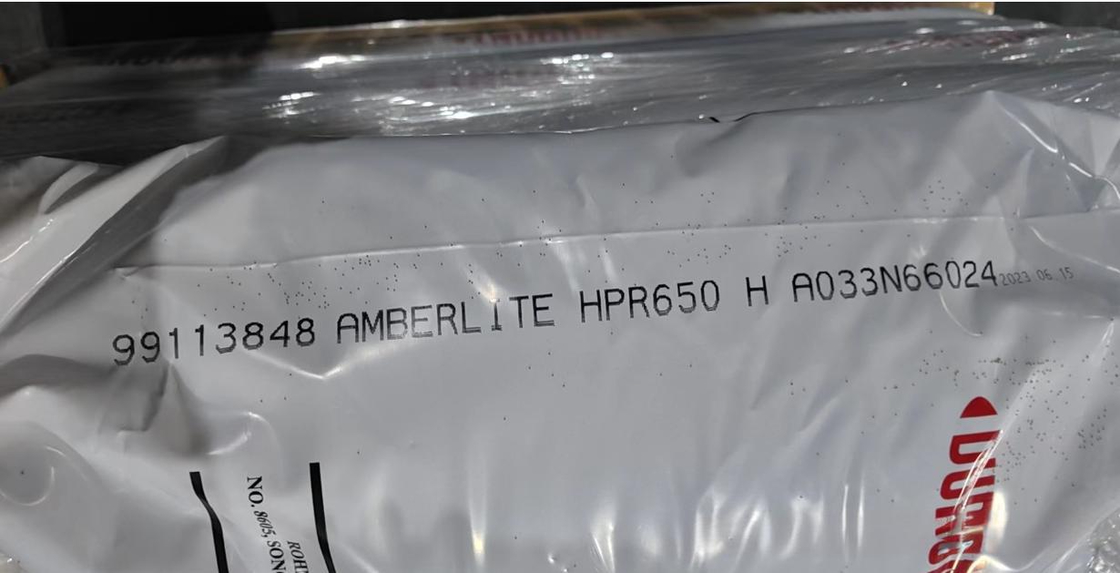

| Brand Name: | Dupont |

| Certification: | ISO9001 |

| Model Number: | DuPont™ AmberLite™ HPR4200 CL |

| Document: | IER-AmberLite-HPR4200-Cl-PD...en.pdf |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1pc |

|---|---|

| Price: | Negotiable |

| Packaging Details: | standard export packing |

| Delivery Time: | 5- 8 work days |

| Payment Terms: | T/T |

| Supply Ability: | 60000 Units per Month |

|

Detail Information |

|||

| HPR4200 CL Main Applications: | Industrial Water Demineralization | HPR4200 CL Whole Uncracked Beads: | ≥ 90% |

|---|---|---|---|

| HPR4200 CL Swelling (Cl⁻ → OH⁻): | 20% | HPR4200 CL Particle Density: | 1.07 G/mL |

| HPR4200 CL Warning: | Strong Oxidizing Agents (e.g., Nitric Acid) May Degrade The Resin Or Cause Violent Reactions. Consult Experts Before Use. | HPR4200 CL Physical Form: | Yellow Translucent Spherical Beads |

| Type: | Strong Base Anion, Type I | ||

| Highlight: | Whole Uncracked Beads Ion Exchange Resin,Swelling 20% AmberLite HPR4200 Cl,Particle Density 1.07 g/mL Water Treatment Resin |

||

Product Description

DuPont™ AmberLite™ HPR4200 Cl Ion Exchange Resin for Industrial Water Demineralization

DuPont™ AmberLite™ HPR4200 Cl is a high-quality, uniform particle size, gel, Type I strong base anion exchange resin designed for industrial water demineralization applications. It is shipped in the chloride (Cl⁻) form.

Product Overview

This resin is engineered to deliver high operating capacity and low pressure drop, which contributes to reduced chemical consumption during regeneration and lower rinsing water requirements, offering cost-effective operation. Its balanced chemical and physical properties make it a versatile and high-performance choice for various water treatment systems.

Applications

- Demineralization

- Ideal for treating water with a high percentage of silica

- Effective for removing strong and weak acids and achieving low silica leakage

- Mixed bed polishing

Compatible System Designs

- Mixed beds

- Packed beds

- Layered beds

- Counter-current / hold-down systems

- Co-current systems

Recommended Resin Pairings

- For mixed beds:

- AmberLite™ HPR1200 H (gel)

- AmberLite™ HPR1300 H (gel)

- For layered beds:

- AmberLite™ HPR9500 (macroporous)

- AmberLite™ HPR9600 (macroporous)

Historical Reference

Previously sold as DOWEX MARATHON™ 4200 Cl Ion Exchange Resin.

Typical Properties

Physical Properties

| Property | Specification |

|---|---|

| Copolymer | Styrene-divinylbenzene |

| Matrix | Gel |

| Type | Strong base anion, Type I |

| Functional Group | Trimethylammonium |

| Physical Form | Yellow translucent spherical beads |

Chemical Properties

| Property | Specification |

|---|---|

| Ionic Form (as shipped) | Cl⁻ |

| Total Exchange Capacity | ≥ 1.30 eq/L (Cl⁻ form) |

| Water Retention Capacity | 49.0 - 55.0% (Cl⁻ form) |

Particle Size Distribution

| Parameter | Specification |

|---|---|

| Particle Diameter | 650 ± 50 μm |

| Uniformity Coefficient | ≤ 1.25 |

| < 300 μm | ≤ 0.3% |

| > 850 μm | ≤ 5.0% |

For additional particle size information, refer to Document No. 45-D00954-en.

Stability

- Whole Uncracked Beads: ≥ 90%

- Swelling (Cl⁻ -> OH⁻): 20%

Density

- Particle Density: 1.07 g/mL

- Shipping Weight: 670 g/L

Operating Conditions

- Temperature Range:

- OH⁻ form: 5 - 60°C (41 - 140°F) †

- Cl⁻ form: 5 - 100°C (41 - 212°F)

- pH Range:

- Service Cycle: 1 - 14

- Stable: 0 - 14

† Operating at elevated temperatures (e.g., >60-70°C) may impact resin life. Consult DuPont technical representatives for details.

Hydraulic Characteristics

- Backwash Expansion: Estimated bed expansion as a function of backwash flow rate and temperature is shown in Figure 1.

- Pressure Drop: Estimated pressure drop as a function of service flow rate and temperature is shown in Figure 2 (valid for clean water at service run start).

(Note: Refer to original document for graphical data.)

Safety & Compliance

Warning: Strong oxidizing agents (e.g., nitric acid) may degrade the resin or cause violent reactions. Consult experts before use.

Users should review safety data sheets (SDS) and ensure compliance with local regulations.

Want to Know more details about this product