High-Quality FRP Tank Ideal For Industrial Applications With Easy Maintenance

Product Details:

| Place of Origin: | China |

| Brand Name: | Fenigal |

| Certification: | CE |

| Model Number: | 1454 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 pc |

|---|---|

| Price: | Negotiable |

| Packaging Details: | standard export packing |

| Supply Ability: | 60000 Units per Month |

|

Detail Information |

|||

| Imperial Size (inch): | 1454 | Tank Diameter & Height (mm): | φ350×1400 |

|---|---|---|---|

| Opening Size (inch): | Top Opening 2.5" Thread | Design Flow Rate (T/H): | 2.5~3.0 |

| Highlight: | Easy Maintenance FRP tank,Industrial FRP tank |

||

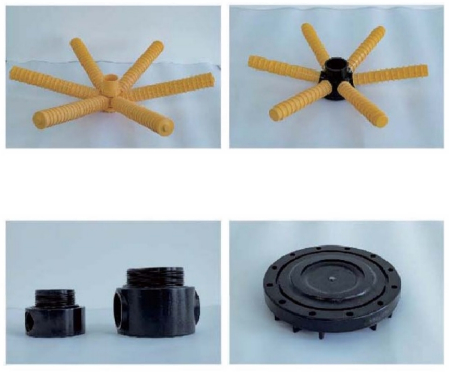

Product Description

Our premium FRP tank is engineered to deliver exceptional performance in various industrial settings. With an imperial size of 1454 inches, it features a diameter and height of φ350×1400mm, ensuring ample capacity for your operational needs. The top opening comes with a 2.5" thread, facilitating conven,

ent installation and connection with other equipment. Boasting a design flow rate of 2.5~3.0 T/H, this tank is perfectly suited for handling medium-volume fluid processing tasks.

Maintenance tips are crucial to extend the lifespan of the FRP tank. Firstly, the FRP storage tank should only be used under designed conditions, and the medium should not be changed arbitrarily. If the medium needs to be changed under designed conditions, it must be cleaned thoroughly. Secondly, avoid contact and collision with sharp and hard objects to prevent surface damage. Thirdly, any damage found should be repaired promptly to prevent further deterioration. Fourthly, prolonged exposure to intense sunlight and harsh environments should be avoided as they can affect the tank's performance and appearance. Fifthly, regular cleaning and sanitization are necessary to maintain hygiene and operational efficiency. Sixthly, periodic waxing, polishing, and painting can help keep the tank looking good and ensure its durability.

In industrial applications, this FRP tank has proven its worth. For example, in a chemical processing plant, it is used to store and transfer corrosive chemicals. Thanks to the excellent corrosion resistance of FRP material, the tank remains intact even after long-term use, ensuring the safe and stable operation of the production line.

![]()

![]()

![]()

![]()