FRP Water Treatment Tank 1365 φ325×1650mm 2.5'' Thread 2.0-2.5 T/H with Superior Anticorrosion

Product Details:

| Place of Origin: | China |

| Brand Name: | Fenigal |

| Certification: | CE |

| Model Number: | 1354 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 pc |

|---|---|

| Price: | Negotiable |

| Packaging Details: | standard export packing |

| Supply Ability: | 60000 Units per Month |

|

Detail Information |

|||

| Specification: | Details | Model Number: | 1365 |

|---|---|---|---|

| Diameter & Height: | φ325×1650mm | Size (inch): | 1365 |

| Top Opening: | 2.5” Thread | Design Flow Rate: | 2.0~2.5 T/H |

| Anticorrosion Layers: | Inner Lining (70%+ Resin), Structural Layer, Outer Protective Layer | Key Resins Used: | Bisphenol A, Vinyl Ester, Epoxy, Furan, Phthalic Resins |

| Application Industries: | Municipal Wastewater, Industrial Effluent, Chemical Water Treatment | Industrial Cases: | Acidic Wastewater Treatment, Alkaline Heavy Metal Wastewater Processing |

| Highlight: | Superior Anticorrosion FRP Water Treatment Tank,FRP Water Treatment Tank 1365 |

||

Product Description

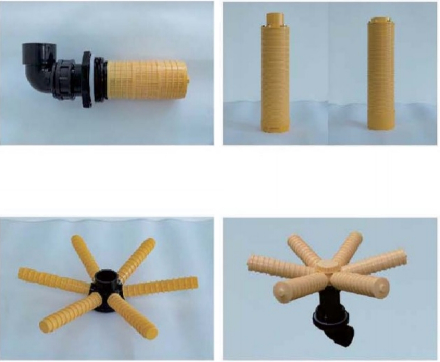

The FRP Water Treatment Tank 1365 is a premier solution for industrial water processing, featuring a diameter and height of φ325×1650mm, a 2.5” threaded top opening, and a design flow rate of 2.0~2.5 T/H. Its standout feature lies in exceptional anticorrosion properties, making it ideal for harsh water treatment environments.

Anticorrosion Characteristics

FRP water treatment tanks owe their superior corrosion resistance to a well-engineered structure, consisting of three layers: inner lining, structural layer, and outer protective layer. The inner lining has a high resin content (over 70%), with the inner surface resin-rich layer reaching approximately 95%. By selecting appropriate resins for the inner lining, the tank can resist different corrosive substances, adapting to various working conditions. For external corrosion protection, careful selection of resins for the outer layer ensures long-term durability.

Based on specific corrosive environments, different anticorrosive resins are used:

This versatility allows the tank to perform reliably in diverse corrosive settings.

Industrial Application Cases

![]()

![]()

![]()

![]()