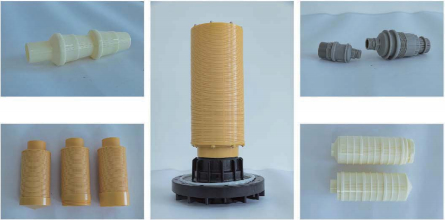

Composite Material Filter Tank 1265 φ300×1650mm 2.5'' Thread 2.0-2.5 T/H for Industrial Filtration

Product Details:

| Place of Origin: | China |

| Brand Name: | Fenigal |

| Certification: | CE |

| Model Number: | 1265 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 pc |

|---|---|

| Price: | Negotiable |

| Packaging Details: | standard export packing |

| Supply Ability: | 60000 Units per Month |

|

Detail Information |

|||

| Specification: | Details | Model Number: | 1265 |

|---|---|---|---|

| Diameter & Height: | φ300×1650mm | Size (inch): | 1254 |

| Top Opening: | 2.5” Thread | Design Flow Rate: | 2.0~2.5 T/H |

| Manufacturing Process: | Computer-controlled, With Inner Lining, Structural Layer, And Protective Layer Fabrication | Raw Materials: | Resins, Fiber Mats, Glass Fiber Winding Yarns |

| Inspection StandardsP[;'\/: | Adhere To National/industry Standards; Special Requirements Follow Relevant Domestic And International Standards | Application Industries: | Metallurgy, Petrochemical, Etc. |

| Industrial Application Cases: | Steel Plant Wastewater Filtration, Petrochemical Oil Product Filtration | ||

| Highlight: | Industrial Filtration Filter Tank,Composite Filter Tank 1265,Industrial Filtration Composite Filter Tank |

||

Product Description

The Composite Material Filter Tank 1265 is a state-of-the-art industrial filtration solution, featuring a diameter and height of φ300×1650mm, a top opening with 2.5” thread, and a design flow rate of 2.0~2.5 T/H. It is designed to meet the most demanding filtration needs across a wide range of industries.

Manufacturing Process

This composite material filter tank is produced under computer control. Firstly, the inner lining layer, such as the corrosion-resistant inner lining, is fabricated on the core mold according to requirements. After gelation, the structural layer is wound with a specified linear pattern and thickness. Finally, the protective layer is added. This precise process ensures the tank's quality and performance.

Raw and Auxiliary Materials

High-quality materials are used in its production, including resins, fiber mats, and glass fiber winding yarns. These materials contribute to the tank's durability, chemical resistance, and filtration efficiency.

Product Production and Inspection Standards

To maintain the high quality and specific performance requirements of the product from start to finish, strict control over each production process, raw material selection, and final product inspection at every step is of utmost importance. The inspection of composite material filter tanks and related devices is a comprehensive quality assurance system. This system requires that both raw and auxiliary materials have certificates of conformity from the manufacturers and meet the product's quality and technical index requirements. Full inspections and random sampling are carried out before production.

Simultaneously, physical and mechanical tests and inspections for corresponding performance requirements are conducted on the composite material filter tanks and related devices. Under normal circumstances, national or industry standards are implemented for the specified manufacturing processes and product performance inspections. In case of special requirements, relevant domestic and international standards are adopted for inspection.

Industrial Application Cases

![]()

![]()

![]()

![]()