2.5'' Thread Top Opening FRP Filter Tank | 0.1-0.2 T/H Design Flow Rate

Product Details:

| Place of Origin: | China |

| Brand Name: | Fenigal |

| Certification: | CE |

| Model Number: | 0818 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 pc |

|---|---|

| Price: | Negotiable |

| Packaging Details: | standard export packing |

| Supply Ability: | 60000 Units per Month |

|

Detail Information |

|||

| Imperial Size (inch): | 0818 | Tank Diameter & Height (mm): | φ200×450 |

|---|---|---|---|

| Opening Size (inch): | Top Opening 2.5” Thread | Design Flow Rate (T/H): | 0.1~0.2 |

| Highlight: | 2.5'' Thread FRP Filter Tank,Opening FRP Filter Tank |

||

Product Description

FRP Filter Tank (φ200×450), a high-performance fiberglass-reinforced plastic water treatment equipment, is widely used in both industrial and civil water purification processes. Combining the superior properties of FRP with advanced softening technology, this tank offers exceptional corrosion resistance, wear resistance, and high-temperature tolerance, ensuring effective removal of impurities and harmful substances from water.

Its well-designed internal structure guarantees a long service life, easy maintenance, and user-friendly operation, making it an economical and practical choice for various water treatment needs. The tank's FRP inner coating prevents corrosion from water-borne substances, enhancing durability during the softening process.

FRP Filter Tanks find extensive applications across almost all sectors requiring water treatment. They are indispensable in industries such as water supply, environmental protection, chemical engineering, food processing, pharmaceuticals, petroleum, textiles, metallurgy, and construction. Additionally, they serve water treatment needs in mines, urban and rural areas, parks, tourist attractions, hotels, and golf courses.

The working principle involves selecting appropriate softeners based on water quality characteristics, then pumping water into the tank for softening. Purified water can be used for production, drinking, and other purposes. These tanks can also be combined with other equipment like granular activated carbon filters and reverse osmosis systems to achieve enhanced treatment efficiency.

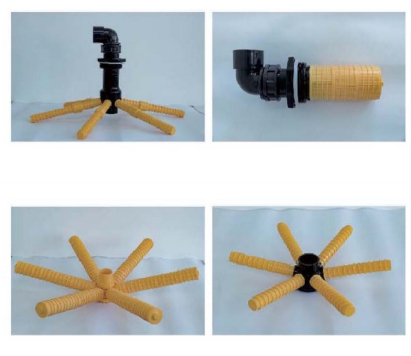

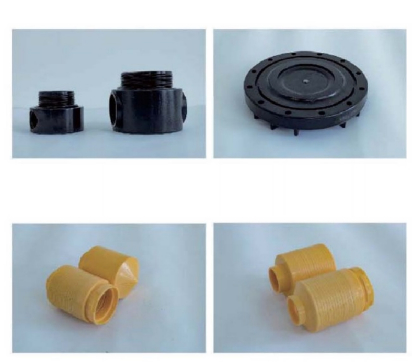

Constructed through four-dimensional winding of reinforcing fibers and high-performance resin on a PE or FRP liner, the water treatment FRP tank is a corrosion-resistant composite pressure vessel. It consists of top/bottom openings, a tank body, a discharge port, and a base. Connections for openings and discharge ports often use high-density, high-strength threads or flanges, while the base is typically made of FRP or reinforced PP.

As a crucial water treatment component, FRP Filter Tanks continuously improve water quality and address diverse water treatment challenges. With technological advancements, their application scope and performance are expected to expand further, meeting evolving industry demands.

![]()

![]()

![]()

![]()