indicates that the incoming water pressure is low (less than 0.1Mpa), the filter element should be changed as well.

1000Lph Double Stages RO+EDI For Industry Water Filtration

Product Details:

| Place of Origin: | China |

| Brand Name: | Fenigal |

| Certification: | CE |

| Model Number: | Ultrapure Water Machine |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 pc |

|---|---|

| Price: | Negotiable |

| Packaging Details: | standard export packing |

| Delivery Time: | 5- 8 work days |

| Supply Ability: | 60000 Units per Month |

|

Detail Information |

|||

| Product Capacity: | 1000L/h | Membrane Vessel: | Stainless Steel SS304 |

|---|---|---|---|

| Pretreatment: | Sand Filter+carbon Filter + RO Membrane | Application: | Sea Water Desaliantion RO Treatment |

| Membrane Optional: | Hydranautics/Vontron/DOW | Pipe: | UPVC |

| Rejection Rate: | 96-99% | Usage: | Industry Water Filtration |

| Highlight: | 1000Lph RO+EDI,Double Stages RO+EDI,Industry Water Filtration RO+EDI |

||

Product Description

1000Lph High Quality Double Stages RO+EDI For Industry Water Filtration

1.Source water inlet: City tap or river or borehole source water TDS is less than 20000ppm.

2.Capacity: Output Ro pure water is 500 liters per hour.

3.Ro output pure water application::Daily consumption or irrigating or food manufacturing.

If your source water or capacity or output water application is not same as above, please kindly send the following details to this supplier for suggesting most suitable quotation

1.Your source water details(city water, well water or river/lake water?). If well/lake/river water, please kindly send water

analysis report.

2.What's the capacity for the RO system you need? (we have experience from 500 lph to 20000lph)

3.What's the output water application?(industrial/commercial/agricultural? drinking water?

Advantages of EDI Technology

2). Constantly produce ultrapure water as per user requirements.

3). Modular production, can achieve automatic control

4). No need acid and alkali regeneration, no pollution emissions.

5). No need stop because of regeneration

6). No need regeneration equipment and chemical storage

7). Compact equipment, small size, saving shipping cost.

8). Low operation and maintenance cost

9). Simple operation and low labor strength.

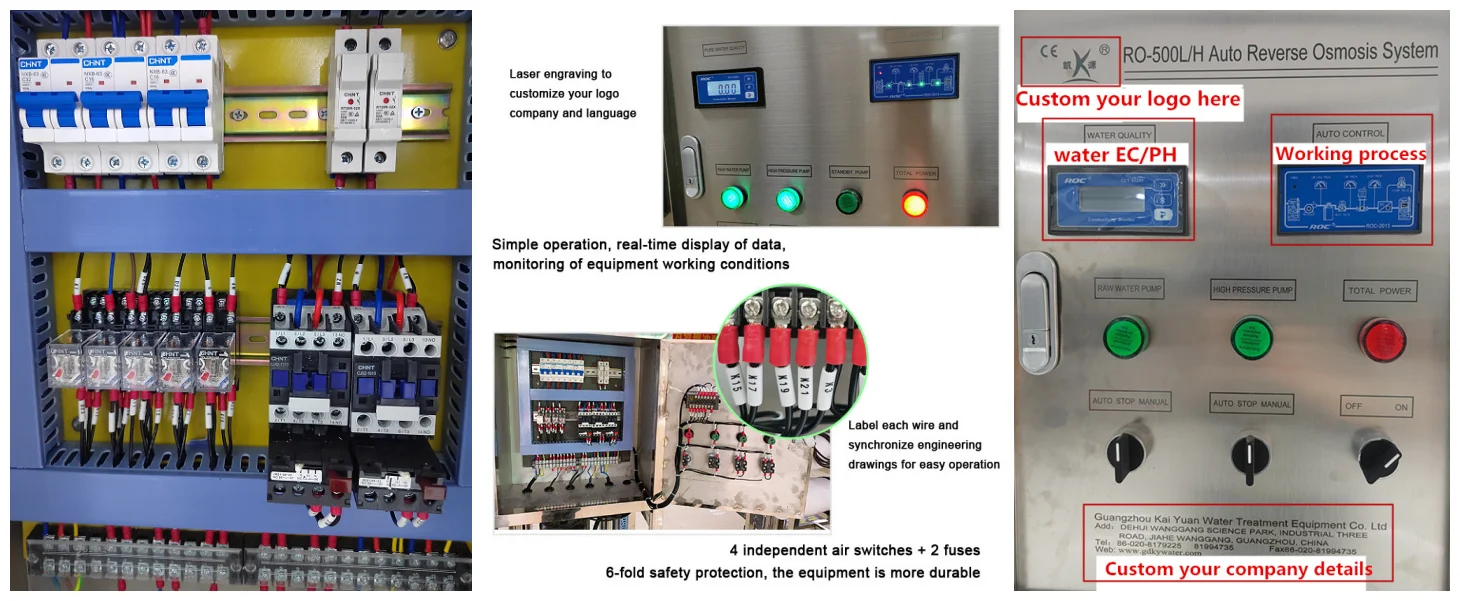

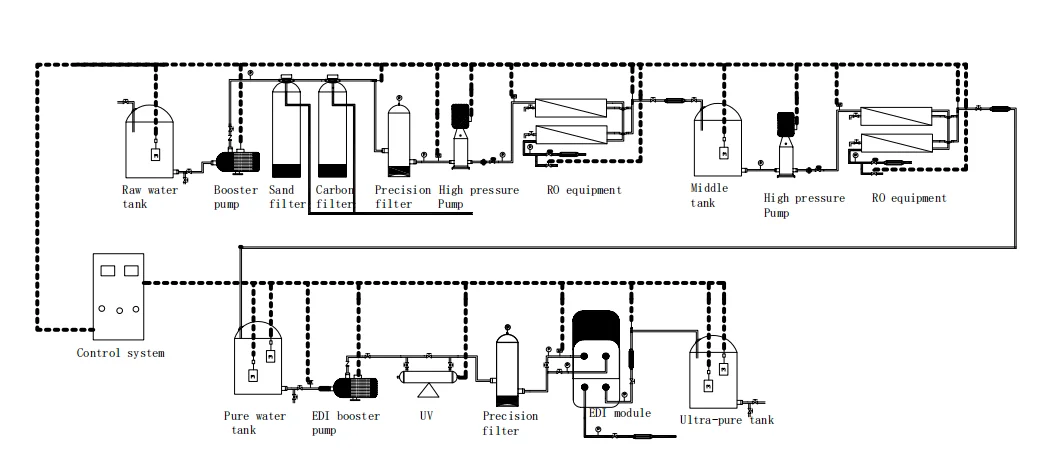

Ultrapure Water Process Flowchart

Raw Water Tank, Sterile water tank and PLC Control

Water Inflow outflow Pump, booster pump

indicates that the incoming water pressure is low (less than 0.1Mpa), the filter element should be changed as well.

![]()

![]()

| Features: | Benefits of EDI: |

|

|

| The ideal applications for an Electro-Deionization Unit include: | ||

|

|

|

![]()

![]()

About Us

FG Water Technologies (www.fgwater.com) is now an organic part of Wuxi Fenigal Science and Technology Co. Ltd., which is a high-tech entity integrating water treatment quipment design, manufacturing, trading and shipment served for main industrial sectors.

HAFE-FG Water Technologies has focused on the research of water treatment technology, equipment development and manufacturing, testing and international shipment etc. We work with many leading large-scale or small-medium original equipment manufacturers in China High-tech Development Zones, and engaged ourselves in R&D, manufacturing, and quality testing.

Our main products include a variety of water purification and different treatment equipment, such as seawater reverse osmosis (SWRO) system, brackish water rever osmosis (BWRO), ultrafiltration (UF)system, Electrodeionization/EDI equipment, media pressure filters and ion exchanger softeners. So far, our company has become a major water treatment equipment supplier for food and beverage industry, pharmaceutical industry, chemical industry, electric power industry, urban water supply industry, municipal and industrial wastewater treatment and more industries, as well as being an exporter to more than 20 countries and regions in Asia, Europe, the Americas, Africa, etc.

OUR CLIENTS

![]()

INDUSTRIES SERVED

![]()

PRODUCTION SYSTEM

Our production system consist of a list of industry-specialized partnership factories accross China. Some of them singularly cover an area of over 10,000 square meters, including 5,000 square meters of workshop and warehouse and 1,500 square meters of office buildings. All of our technical staff has more than 10 years of experience in the design of water treatment systems, so we are able to provide the perfect solution for all kinds of water purification and sewage treatment applications.

Since the establishment, the Company has always regarded quality as the life of our business. We choose the best components only for the production of various water treatment systems. Our systems are easy to use and maintain, and they stays highly reliable even under toughest conditions.

Our FACTORY

![]()