150m3/H Industrial Water Clarifier

Product Details:

| Place of Origin: | China |

| Brand Name: | Fenigal/OEM |

| Certification: | CE/ISO etc. |

| Model Number: | LC1 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 Set |

|---|---|

| Price: | Negotiable |

| Packaging Details: | Standard Export Wood Crate/Carton or Naked wrapped by film/Containerized |

| Delivery Time: | 15~30 days |

| Payment Terms: | T/T, Western Union, Paypal etc. |

| Supply Ability: | 200 set per month |

|

Detail Information |

|||

| Technology: | Sedimentation Tank Theory | Membrane: | Carbon Sheet Steel/PP Plate |

|---|---|---|---|

| Design: | Skid Mount/containerized | Water Temp.: | 5~35˚C |

| Water Flow Rate: | Up To 1,000 M3/day | Voltage: | 380V,415V,220V,can Be Customized |

| Application: | Surface-ground Water/sewage Water Clarification | Control: | Electronic,Manual/PLC |

| Highlight: | 220V Industrial Water Clarifier,Lamella Industrial Water Clarifier,150m3/H DAF wastewater treatment system |

||

Product Description

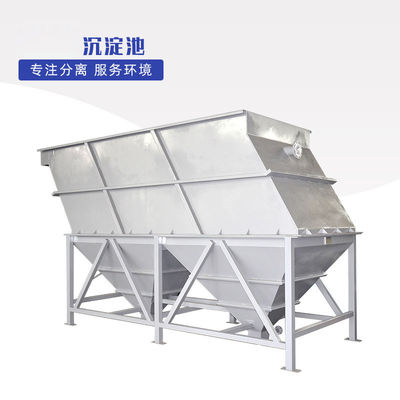

Lamella Clarifier for industrial sewage or waste water clarification 150m3/h Conical Bottom

Lamella clarifier (inclined-plate clarifier) is designed to remove particulates from liquids.LST1 is of simple structure, no energy consumption, and it could be detached and assembled on site in order to meet the transportation requirements.

Lamella clarifier is a high efficient solid-liquid separation device equipped with a series of inclined plates with smaller footprint comparing with traditional sedimentation tank.

LC1 is of simple structure, no energy consumption, and it could be detached and assembled on site in order to meet the transportation requirements.

Process principle and mechanism

Lamella Clarifier system is based on the "shallow tank theory" of German Hazen professor put forward by the early 20th century.Core theory is : sedimentation performance depends on effective settling area, nothing to do with sedimentation depth.Lamella clarifier system settling area is inclined plate projection area accumulation.

Principle of the sedimentation

Lamella clarifier is a high efficient solid-liquid separation device equipped with a series of inclined plates with smaller footprint comparing with traditional sedimentation tank

Characteristics and advantages:

1.Higher efficiency, smaller footprint: inclined plates extended to 1.5m, separation efficiency improved (higher 1.5 ~ 2.0 times) comparing with radial flow clarifier and vertical clarifier and save 80% of area.

2.Excellent hydraulic conditions: no hydraulic dead corner and vortex, better settling performance.

3. Inclined plates Chokeless :plates are of angle 60 degrees, spacing between 80 ~ 100 mm, adopting the back-washing device.

4. Strong and durable: Inclined plates are breakless, collapseless. Adopting 6mm hard PVC board or 8 mm high quality PP board as special separation plate, module embedded installation, high strength, easy disassembling and maintenance.

5.Sludge discharge smoothly : no dead angle, sludge pump is recommended .

LC1 Lamella Clarifier of conical bottom (without scraper) Specification

| Model | Capacity | Dimension(m) | Nozzle list(DN)GB/JIS/ANSL | |||||

| (m3/h) | L | W | H1/H2 | Inlet | Outlet | Sludge outlet | Backwash | |

| LC1-001 | ~1 | 1.6 | 0.8 | 2.0/2.0 | 25 | 25 | 50 | 50 |

| LC1-003 | ~3 | 1.6 | 1.1 | 2.0/2.0 | 50 | 50 | 50 | 50 |

| LC1-005 | ~5 | 2.6 | 1.6 | 2.9/2.9 | 80 | 50 | 50 | 50 |

| LC1-010 | ~10 | 3.4 | 1.8 | 3.6/1.8 | 100 | 80 | 50 | 50 |

| LC1-020 | ~20 | 3.4 | 2.2 | 3.6/1.8 | 150 | 100 | 50 | 50 |

| LC1-030 | ~30 | 4.2 | 2.2 | 4.0/2.2 | 150 | 150 | 50 | 50 |

| LC1-040 | ~40 | 5.3 | 2.2 | 3.6/1.8 | 200 | 150 | 50*2 | 50 |

| LC1-050 | ~50 | 6.3 | 2.2 | 3.8/2.0 | 200 | 200 | 50*2 | 50 |

| LC1-060 | ~60 | 7.2 | 2.2 | 4.0/2.2 | 250 | 200 | 50*2 | 50 |

| LC1-070 | ~70 | 7.2 | 2.6 | 4.0/2.2 | 250 | 200 | 50*2 | 50 |

| LC1-080 | ~80 | 7.2 | 2.7 | 4.0/2.2 | 250 | 200 | 80*2 | 50 |

| LC1-090 | ~90 | 6.7 | 3.1 | 4.0/2.2 | 250 | 250 | 80*2 | 50 |

| LC1-100 | ~100 | 7.2 | 3.1 | 4.0/2.2 | 250 | 250 | 80*2 | 50 |

| LC1-120 | ~120 | 8.3 | 3.3 | 4.0/2.2 | 250 | 250 | 80*2 | 50 |

| LC1-150 | ~150 | 9.8 | 3.3 | 4.0/2.2 | 250 | 250 | 80*2 | 50 |

LC2 Lamella Clarifier of flat bottom (with scraper) Specification

| Model | Capacity | Dimension(m) | Sludge scraper | Nozzle list (DN) GB/JIS/ANSL | |||||

| (m3/h) | L | W | H1/H2 | kw | Inlet | Outlet | Sludge outlet | Backwash | |

| LC2-005 | ~5 | 2.6 | 1.6 | 3.4/2.5 | 0.25 | 80 | 50 | 50 | 50 |

| LC2-010 | ~10 | 3.4 | 1.8 | 3.8/3.0 | 0.25 | 100 | 80 | 50 | 50 |

| LC2-020 | ~20 | 3.4 | 2.2 | 3.8/3.0 | 0.25 | 150 | 150 | 50 | 50 |

| LC2-030 | ~30 | 4.2 | 2.2 | 3.8/3.0 | 0.25 | 150 | 150 | 50 | 50 |

| LC2-040 | ~40 | 4.0 | 2.8 | 3.8/3.0 | 0.25 | 200 | 200 | 50 | 50 |

| LC2-040 | ~40 | 5.3 | 2.2 | 3.8/3.0 | 0.25*2 | 200 | 150 | 50*2 | 50 |

| LC2-050 | ~50 | 4.7 | 2.8 | 3.8/3.0 | 0.25 | 200 | 200 | 50 | 50 |

| LC2-050 | ~50 | 6.3 | 2.2 | 3.8/2.0 | 0.25*2 | 200 | 200 | 50*2 | 50 |

| LC2-060 | ~60 | 4.8 | 3.0 | 3.8/3.0 | 0.25 | 250 | 200 | 50 | 50 |

| LC2-060 | ~60 | 7.2 | 2.2 | 3.8/3.0 | 0.25*2 | 250 | 200 | 50*2 | 50 |

| LC2-070 | ~70 | 5.1 | 3.2 | 3.8/3.0 | 0.25 | 250 | 200 | 80 | 50 |

| LC2-080 | ~80 | 5.1 | 3.4 | 4.0/3.2 | 0.25 | 250 | 250 | 80 | 50 |

| LC2-090 | ~90 | 6.3 | 3.0 | 4.0/3.2 | 0.25*2 | 250 | 250 | 80*2 | 50 |

| LC2-100 | ~100 | 7.1 | 3.0 | 4.0/3.2 | 0.25*2 | 250 | 250 | 80*2 | 50 |

| LC2-110 | ~110 | 7.8 | 3.0 | 4.0/3.2 | 0.25*2 | 300 | 250 | 80*2 | 50 |

| LC2-120 | ~120 | 8.3 | 3.0 | 4.0/3.2 | 0.25*2 | 300 | 300 | 80*2 | 50 |

Application Industry

Electronic wastewater

Chemical phosphorus removal

Electroplating wastewater

Paper and pulp wastewater

Wastewater before filter or back-washing wastewater treatment

Advanced treatment of the WWTP

River purification

![]()

![]()

![]()