1465 Inch Corrosion-Resistant FRP Tank φ350×1650mm 2.5-3.0T/H Industrial Filter with 2.5” Thread Top Opening

Product Details:

| Place of Origin: | China |

| Brand Name: | Fenigal |

| Certification: | CE |

| Model Number: | 1465 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 pc |

|---|---|

| Price: | Negotiable |

| Packaging Details: | standard export packing |

| Supply Ability: | 60000 Units per Month |

|

Detail Information |

|||

| Size(inch): | 1465 | Diam&Height(mm): | φ350×1650 |

|---|---|---|---|

| Opening(inch): | Top Opening 2.5” Thread | Design Flow Rate(T/H): | 2.5~3.0 |

| Highlight: | Corrosion-Resistant FRP Tank,Industrial Filter FRP Tank |

||

Product Description

Our corrosion-resistant FRP tank is a high-performance filtration solution designed for industrial applications. With an imperial size of 1465 inches, it features a diameter and height of φ350×1650mm, ensuring efficient filtration of liquids or gases. Equipped with a top opening of 2.5” thread, it operates at a design flow rate of 2.5~3.0 T/H, making it ideal for various impurity removal tasks.

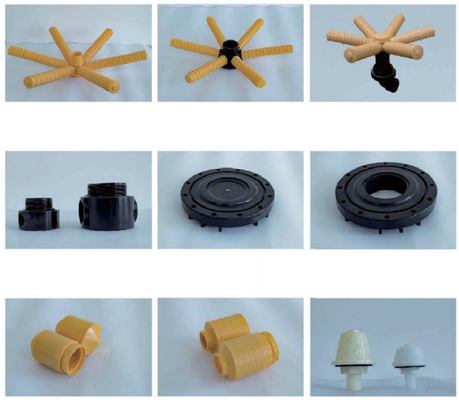

A filter tank is mainly used to filter impurities in liquids or gases, with its core structure consisting of four parts: shell, filter material, water/gas inlets and outlets, and seals. The shell, typically made of stainless steel, plastic, or FRP, supports and protects the internal components, while the interior is filled with different filter media. When liquid or gas enters from the inlet, impurities are intercepted by the filter material, and the purified substance flows out from the outlet.

The shell's material depends on the operating environment. For industrial wastewater treatment, FRP is preferred for its corrosion resistance. Its thickness is adjusted according to pressure; high-pressure environments require thicker materials to prevent bursting. Observation windows or pressure gauges are often installed on the top or side for easy monitoring.

Filter materials are the core, including activated carbon, quartz sand, PP cotton, and ceramic filters. Activated carbon adsorbs residual chlorine and organic matter; quartz sand filters large particles; PP cotton intercepts tiny suspended solids; ceramic filters can filter particles larger than 0.1 microns. Multi-layer filter tanks combine materials, such as stainless steel mesh for stones, quartz sand for sediment, and activated carbon for odors.

Inlet and outlet positions are strategic. Vertical tanks usually have top-in and bottom-out designs to utilize gravity for full contact with filter materials; horizontal tanks use Z-shaped channels to extend contact time. Anti-leak gaskets are added at interfaces, and some tanks have backwash ports to flush out impurities.

Seals are made of silica gel or rubber. A tight seal between the lid and cylinder is crucial to avoid unfiltered leakage. Seals should be checked for aging every six months, especially when handling high-temperature liquids. Industrial tanks with flange connections require bolts to be tightened diagonally to prevent uneven stress leakage.

Industrial application case: A chemical plant uses this FRP filter tank to purify corrosive wastewater. Filled with quartz sand and activated carbon, it removes sediment and organic pollutants, ensuring the treated water meets discharge standards. The FRP shell resists chemical corrosion, reducing maintenance frequency and extending service life.

![]()

![]()

![]()

![]()