2200GPD Marine Reverse Osmosis Water Maker

Product Details:

| Place of Origin: | China |

| Brand Name: | Fenigal/OEM |

| Certification: | CE/UL/NSF etc. |

| Model Number: | SR-600GPD~2,200GPD |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 Set |

|---|---|

| Price: | Negotiable |

| Packaging Details: | Standard Export Wood Crate/Carton or Naked wrapped by film |

| Delivery Time: | 15~30 days |

| Payment Terms: | T/T, Western Union, Paypal etc. |

| Supply Ability: | 50 set per month |

|

Detail Information |

|||

| Technology: | Reverse Osmosis | Design: | Skid Mount |

|---|---|---|---|

| Recovery Rate: | 8~40% | Feed TDS/ppm: | <42,000 |

| Material: | SS304/SS316L,carbon Steel | Voltage: | 380V,415V,220V,can Be Customized |

| Ro Membrane: | Hydranautics Or DOW,4040 | Pump: | Danfoss/CAT/CNP |

| Highlight: | 2200GPD marine reverse osmosis water maker,SS316L marine reverse osmosis water maker,2200GPD marine ro water maker |

||

Product Description

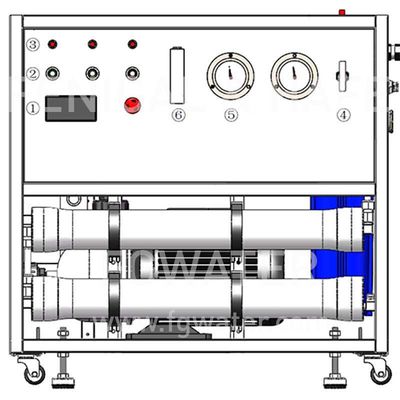

SR series Seawater Reverse Osmosis Desalination Watermakers 600GPD~2,200GPD

SR – Series Reverse Osmosis Systems are engineered and manufactured for seawater

applications specifically tailored for capacities ranging from 600 to 2,200 gallons per day. The

SR – Series Reverse Osmosis Systems feature a unique and innovative compact design that allows for easy installation in any size area.

The SR – Series is also equipped with premium components, which include a 316L SS plunger–type pump for high performance, a high grade corrosion resistant aluminum frame, a programmable computer controller with many built–in features and fiberglass membrane housings for durability.

Benefits

Fully Equipped and Customizable

High Quality Components

Individually Tested and Preserved

Low Operating and Maintenance Costs

Easy Maintenance and Servicing

Pre–Plumbed, Wired and Assembled

1–Year Limited Warranty

Features

|

Micro-computer Controller LCD Backlit Display Pre–Treatment Lockout Tank Level Input Pressure Monitoring and Alarm TDS Monitoring Hour Meter Feed Flush High RejectioSeawater Membranes FRP Membrane Housings MicroSediment Pre–Filter Permeate and Concentrate Flow Meters 0 – 100 psi 316L – SS Glycerin–Filled Filter Pressure Gauge |

0 – 100 psi 316L – SS Glycerin–Filled Pre–Filter Out Pressure Gauge 0 – 1500 psi 316L – SS Glycerin–Filled Concentrate Pressure Gauge Feed Solenoid Valve 316L Stainless Steel Needle Valve 316L SS Feed Low Pressure Switch 316L SS High Pressure Pump Switch 316L High Pressure Pump TEFC Motor with Thermal Motor Protection Chemical Pump Outlet Powder Coated Aluminum Frame High Pressure 316L Stainless Steel Tubing and Fittings High Pressure Hose with Reusable SS Fittings |

Options and Upgrades

Booster Pump

High Pressure Tank Switch

Permeate Divert Valve

Fresh Water Flush

Ultraviolet Light

Wooden Shipping Crate

Array Specifications

Technical specifications

| Models | SR – 1125 | SR – 2125 | SR – 3125 | SR – 4125 |

| Design | ||||

| Configuration | Single Pass | Single Pass | Single Pass | Single Pass |

| Feedwater Source† | TDS <35,000 ppm | TDS <35,000 ppm | TDS <35,000 ppm | TDS <35,000 ppm |

| Standard Recovery Rate % | 10 | 20 | 25 | 36 |

| Rejection and Flow Rates††† | ||||

| Nominal Salt Rejection % | 99 | 99 | 99 | 99 |

| Permeate Flow (gpm / lpm) | 0.41 / 1.55 | 0.83 / 3.14 | 1.25 / 4.73 | 1.52 / 5.75 |

| Minimum Feed Flow (gpm / lpm) | 4.20 / 15.90 | 4.20 / 15.90 | 4.20 / 15.90 | 4.20 / 15.90 |

| Connections | ||||

| Feed FNPT (in) | 1/2 | 1/2 | 1/2 | 1/2 |

| Permeate Tubing (in) | 3/8 | 3/8 | 3/8 | 3/8 |

| Concentrate Tubing (in) | 3/8 | 3/8 | 3/8 | 3/8 |

| Membranes | ||||

| Membrane Per Vessel | 1 | 1 | 1 | 1 |

| Membrane Quantity | 1 | 2 | 3 | 4 |

| Membrane Size | 2540 | 2540 | 2540 | 2540 |

| Vessels | ||||

| Vessel Array | 1 | 1:1 | 1:1:1 | 1:1:1:1 |

| Vessel Quantity | 1 | 2 | 3 | 4 |

| Pumps | ||||

| Pump Type | Plunger | Plunger | Plunger | Plunger |

| Motor (HP / kw) | 2.50 / 1.85 | 2.50 / 1.85 | 2.50 / 1.85 | 2.50 / 1.85 |

| RPM @ 60Hz (50 Hz) | 1725 / 1450 | 1725 / 1450 | 1725 / 1450 | 1725 / 1450 |

| System Electrical | ||||

| Standard Voltage + Amp Draw | 220VAC, 1PH, 11.9A** | 220VAC, 1PH, 11.9A** | 220VAC, 1PH, 11.9A** | 220VAC, 1PH, 11.9A** |

| Systems Dimensions | ||||

| Approximate Dimensions* L x W x H (in / cm) | 45.625 X 18 X 26.75 / 115.9 X 45.7 X 67.9 |

45.625 X 18 X 26.75 / 115.9 X 45.7 X 67.9 |

45.625 X 18 X 26.75 / 115.9 X 45.7 X 67.9 |

45.625 X 18 X 26.75 / 115.9 X 45.7 X 67.9 |

| Approximate Weight (lbs / kg) | 145 / 65.77 | 155 / 70.31 | 165 / 74.84 | 175 / 79.38 |

Test Parameters: 35,000 TDS Filtered (5 – Micron), Dechlorinated, Municipal Feedwater, 45 psi / 3.1 bar Feed Pressure, 850 psi / 58.61 bar Operating Pressure, 77ªF / 25ªC, Recovery as stated, 7.0 pH. Data taken after 60 minutes of operation.

* Does not include operating space requirements.

** Varies with motor manufacturer.

Operating Limits

| Maximum Feed Temperature (°F / °C) | 85 / 29 | Maximum Turbidity (NTU) | <1 |

| Minimum Feed Temperature (°F / °C) | 41 / 5 | Maximum Free Chlorine (ppm) | 0 |

| Maximum Ambient Temperature (°F / °C) | 120 / 49 | Maximum Hardness (gpg) | 0 |

| Minimum Ambient Temperature (°F / °C) | 40 / 4 | Maximum pH (Continuous) | 11 |

| Maximum Feed Pressure (psi / bar) | 60 / 4 | Minimum pH (Continuous) | 2 |

| Minimum Feed Pressure (psi / bar) | 15 / 1 | Maximum pH (Cleaning 30 Minutes) | 13 |

| Maximum Operating Pressure (psi / bar) | 1000 / 69 | Minimum pH (Cleaning 30 Minutes) | 1 |

| Maximum Feed Silt Density Index (SDI) | <3 |

Low temperatures and feedwater quality, such as high TDS levels will significantly affect the systems production capabilities and performance. Computer projections must be run for individual applications which do not meet or exceed minimum and maximum operating limits for such conditions.

System pressure is variable due to water conditions. Permeate flow will increase at a higher temperature and will decrease at a lower temperature.

Product flow and maximum recovery rates are based on feedwater conditions as stated above. Do not exceed recommended permeate flow.

![]()

More information about SWRO

What is seawater reverse osmosis?

Seawater reverse osmosis systems are designed to decline more than 99% of saline compromised within the feed water. These systems also incorporate a rinsing, chemical purifying apparatus to eliminate sodium chloride, avert scaling, and preserve system performance. There are two fundamental elements within every seawater reverse osmosis system, which are reverse osmosis membranes and high pressure feed pumps. These elements make up the center of any reverse osmosis system and need special consideration and application for successful operation.

Does reverse osmosis remove salt from seawater?

Yes, semipermeable membranes enable the feed water to pass through it at a much higher volume than dissolved salts. Reverse osmosis systems work by applying pressure as freshwater streams through its membranes to filter out the concentrated saline in the feed water, as well as minerals and pollutants. These unwanted impurities are either flushed away, recycled, or processed. Seawater reverse osmosis systems utilize more than one membrane to boost the load of purified water turned out each day.

What are the advantages of desalination plants?

Seawater desalination has become a vital alternative to the production of pure freshwater throughout the areas of the world without drinkable water. As other sources such as rivers, lakes, wells, and springs have become more exhausted due to excessive extraction, the ocean has provided an abundant supply of available water for human use. Although ocean water consists of elevated levels of salt, and therefore is unable to be utilized for consumption or most other purposes, seawater desalination has helped make it practical.