5000TPD Ultrafiltration Water Treatment Plant

Product Details:

| Place of Origin: | China |

| Brand Name: | Fenigal/OEM |

| Certification: | CE/UL/NSF etc. |

| Model Number: | UF-1-1 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 Set |

|---|---|

| Price: | Negotiable |

| Packaging Details: | Standard Export Wood Crate/Carton or Naked wrapped by film |

| Delivery Time: | 15~30 days |

| Payment Terms: | T/T, Western Union, Paypal etc. |

| Supply Ability: | 50 set per month |

|

Detail Information |

|||

| Technology: | Ultrafiltration | Design: | Skid Mount |

|---|---|---|---|

| Permeate Flow/TPD: | 38~1500/skid | Permeate Flow/GPD: | 10,000~403,000 |

| Recovery Rate: | 90~98% | Feed TDS/ppm: | <35,000 |

| Water Temp.: | 5~35˚C | PH: | 2~11 |

| TSS/mg/L: | <100 | Tubidity: | <300 |

| Free Chlorine Mg/L: | 0 | Dissolved Iron Mg/L: | <0.1 |

| Warranty: | 1 Year | Skid Material: | SS304/SS316L,carbon Steel |

| Voltage: | 380V,415V,220V,can Be Customized | Application: | Water Purification,Filtration,pharmceutical,drinking Water,food |

| Size: | Depends,1750*550*1650mm | Function: | Water Purifying, RO Pre-treatment |

| Desalination Rate: | 99%,99.7% | Control: | Electronic,Manual/PLC |

| UF Membrane: | Hydranautics Or DOW / China Make | Pump: | CNP / Grundfos,CNP |

| Highlight: | 5000TPD ultrafiltration water treatment plant,SS304 ultrafiltration water treatment plant,5000TPD UF system water treatment |

||

Product Description

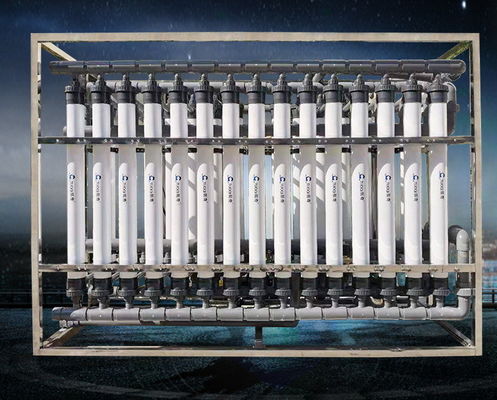

Skid ultrafiltration(UF) hollow fiber purification system 20TPD~80TPD

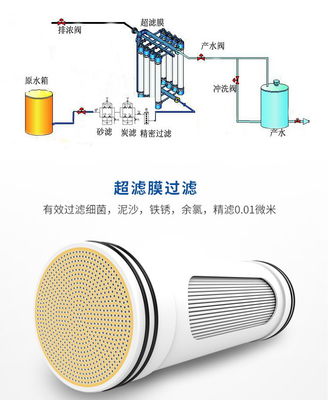

Ultrafiltration (UF) plants are designed to treat ground water, surface water, tertiary treated effluent, storm water or wastewater with turbidity <300 NTU. The standard treatment process includes pre-screening (bag filter or self-cleaning screen filter), outside-to-inside capillary ultrafiltration modules, automated air scouring and maintenance cleaning (MC) system, as well as a CIP system for periodic recovery cleaning (RC). The UF system can be configured as either: dead-end for lower turbidity applications, or cross-flow for higher turbidity applications.

STANDARD SPECIFICATIONS UF-M/L

| Parameter | Units | UF-M-100 | UF- M-200 | UF-M-500 | UF-L-1000 | UF- L-2000 | UF- L-3500 | UF- L-5000 | |

| Filtrate flow rate (min/max)*1 | Low turbidity feed (<100 NTU) | m3/ day |

54~100 | 108~200 | 269~500 | 538~1,000 | 1,077~2,000 | 1,077~3,500 | 2,692~5,000 |

| High turbidity feed (<300 NTU) | 37~69 | 74~138 | 185~346 | 369~692 | 738~1,385 | 1,292~2,423 | 1,846~3,462 | ||

| Power consumption*2 | Plant / equipment | kW | 1.7 | 3.5 | 4.4 | 8 | 11.5 | 15.5 | 22.5 |

| Air conditioned containers*3 | 1.9 per 20’ container, 3.8 per 40’ container (includes internal lighting) | ||||||||

| Power supply | - | AC 415 V, 3 Phase, 50 Hz | |||||||

| Recovery rate*1 | Low turbidity feed (<100 NTU) | % | 92~98% (dead-end configuration) | ||||||

| High turbidity feed (<300 NTU) | 88~92% (cross-flow configuration) | ||||||||

| Average gross flux*1 | Low turbidity feed (<100 NTU) | L/m2/hr | 35~65 (dead-end configuration) | ||||||

| High turbidity feed (<300 NTU) | 24~45 (cross-flow configuration) | ||||||||

| UF membrane pore size | μm | 0.08 | |||||||

| UV dose rate*1 | mJ/cm2 | Typical >40 @ 90% UVT | |||||||

| Pressure | Feed water inlet | kPa | >20 (flooded suction) | ||||||

| Filtrate discharge | 150~200 | ||||||||

| Wastewater discharge | 0 (gravity drain) | ||||||||

| Ambient temperature (min/max) |

Skid mounted | °C | 5~30 | ||||||

| Containerised | -5~40 | ||||||||

| Containerised with insulation | -15~50 | ||||||||

Ultrafiltration (UF) Systems Advantages

Ultrafiltration (UF) membranes systems are more reliable than a conventional multi-media filter, which removed approximately 10 micron or larger of matter, where an ultrafiltration membrane pore size ranges from 0.01 to 0.10 micron. In addition to superior turbidity removal, UF membranes efficiently remove bacteria and most viruses.

- Superior filtration performance with high flux

- Very small nominal pore diameter (0.03 µm)

- Efficiently removes bacteria and viruses

- Occasionally back washed and air scoured to boost performance and removing the fouling layer to extend operating life

- Low fouling membrane modules

- UF Outside-In or Inside-Out Configuration permits reduced plugging and higher solids loading

- Basic, vertical, modular design permits low cost, compact systems

- Effective membrane cleaning has a high chemical resistance and temperature tolerance

![]()

![]()