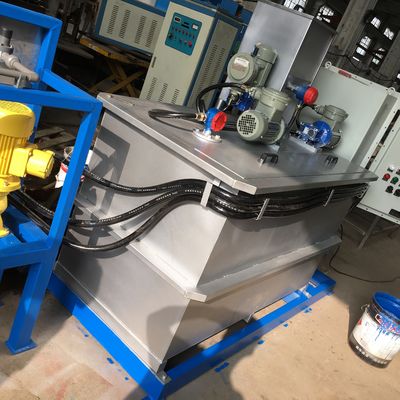

316L Polymer Preparation Unit

Product Details:

| Place of Origin: | China |

| Brand Name: | Fenigal/OEM |

| Certification: | CE/NSF etc. |

| Model Number: | CDS-9 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 Set |

|---|---|

| Price: | Negotiable |

| Packaging Details: | Standard Export Wood Crate/Carton or Naked wrapped by film |

| Delivery Time: | 15~30 days |

| Payment Terms: | T/T, Western Union, Paypal etc. |

| Supply Ability: | 200 set per month |

|

Detail Information |

|||

| Technology: | Chemical Disinfection | Design: | Skid Mount |

|---|---|---|---|

| Water Temp.: | 5~35˚C | Application: | Chemical Dosing |

| Water Flowrate: | 500~10000 L/H | Voltage: | 380V,415V,220V,can Be Customized |

| Control: | Electronic,Manual/PLC | ||

| High Light: | 316L polymer preparation unit,prominent polymer preparation unit,10000L/h polymer dosing system |

||

Product Description

316L Polymer Preparation Unit

Polymer Preparation Units PAM/PAC Tanks available in PE, 316L/304L S.S 200-10000L/hr

Automatic polymer dosing system is a range of simple and flexible as well as economic and efficient preparation systems for polymers. After forming small flocs in the coagulation step (see coagulation), flocculant is dosed in order to create bigger and more stable flocs.

The flocculant is often called polymer or poly-electrolyte. Flocculant poly-electrolyte must be prepared from a powder polymer or a fluid concentrated polymer. Polymer is a product that must be well mixed with water to prevent clot formation. After mixing with water a certain maturation time is necessary to "unfold" the polymer chain. Flocculants needs to "mature" about 30 to 60 minutes before it can be dosed. Matured polymer is a sticky liquid. For larger installations we recommend automatic polymer dosing systems for both powder and liquid polymer applications. An automatic polymer dosing systems consists mostly of three compartments with a dosing screw and a powder storage. In the first area the powder is mixed with water. The ratio water powder can be set-up perfectly. The second area is a maturation tank with stirrer .From the third area the matured polymer is pumped into the flocculator. A level probe mounted in an acrylic holder controls the make-up station. The dosing screw at the bottom of the powder storage is provided with a heating element to prevent condensation. In a polymer make up station of liquid polymer, the entire powder buffer and dosing screw is replaced by a polymer dosing pump.

![]()

![]()

| PT Model |

Capacities (L/h) |

Tank volume (L) | Influent volume | Aging Time | Piping Connections() | Physical Dimensions(mm) | Weight (Kg) |

Power | |||||

| (m3/h) | (h) | Inlet | Dosing | Vent | Overflow | L/L1 | W/W1 | H | (KW) | ||||

| PT200 | 200 | 350 | 0.12-0.6 | 1.0-1.5 | DN20 | DN20 | DN20 | DN32 | 940/860 | 470/520 | 1450 | 250 | 0.54 |

| PT430 | 430 | 750 | 0.3-1.5 | 1.0-1.5 | DN25 | DN25 | DN25 | DN32 | 1370/1290 | 680/730 | 1450 | 350 | 0.92 |

| PT958 | 958 | 1580 | 0.6-3 | 1.0-1.5 | DN25 | DN25 | DN25 | DN40 | 1800/1720 | 900/950 | 1620 | 480 | 1.3 |

| PT1340 | 1340 | 2200 | 0.8-4 | 1.0-1.5 | DN32 | DN32 | DN25 | DN40 | 2130/2050 | 1070/1120 | 1620 | 560 | 1.7 |

| PT2660 | 2660 | 4050 | 1.6-8 | 1.0-1.5 | DN40 | DN40 | DN40 | DN50 | 2450/2370 | 1220/1270 | 2000 | 790 | 2.4 |

| PT4165 | 4165 | 6170 | 2.4-12 | 1.0-1.5 | DN40 | DN40 | DN40 | DN65 | 2780/2700 | 1390/1440 | 2250 | 1050 | 3.2 |

| PT6660 | 6660 | 9610 | 4.2-20 | 1.0-1.5 | DN50 | DN50 | DN40 | DN65 | 3100/3020 | 1550/1600 | 2650 | 1200 | 4.8 |

| PT10940 | 10940 | 15780 | 6-30 | 1.0-1.5 | DN65 | DN65 | DN50 | DN80 | 3970/3890 | 1990/2040 | 2650 | 1450 | |